Where can I use Beam and Block?

Where can Beam & Block be used?

Core uses of Beam & Block Slab:

Ground Floor Slab

Ground Floor Slab

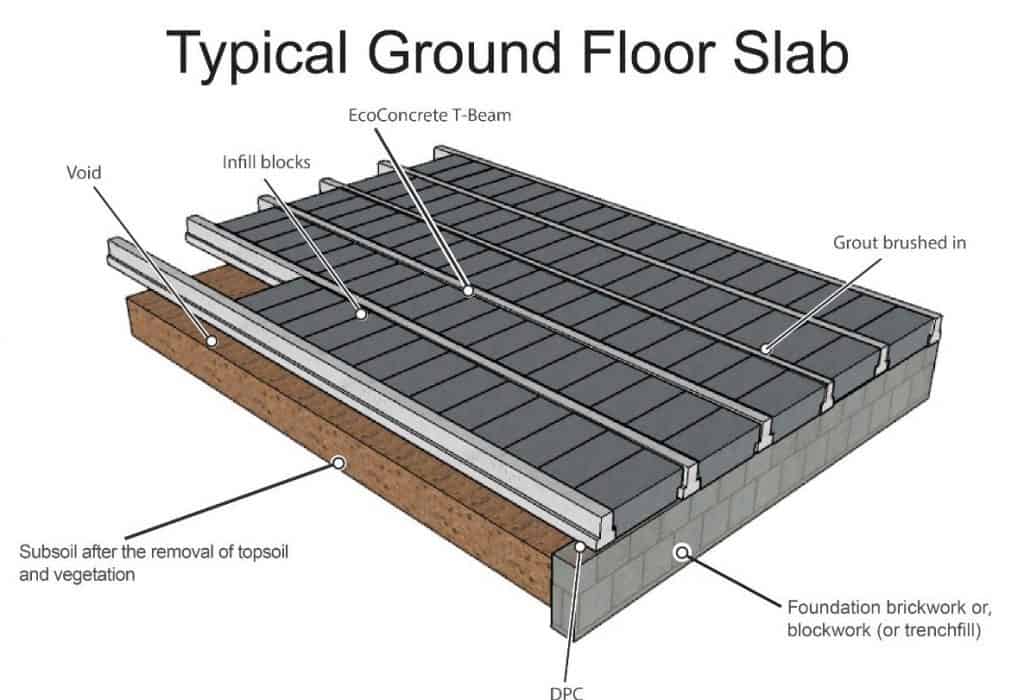

For the ground floor slab, there is no need for mass excavation, simply remove the topsoil and trench for the foundation walls.

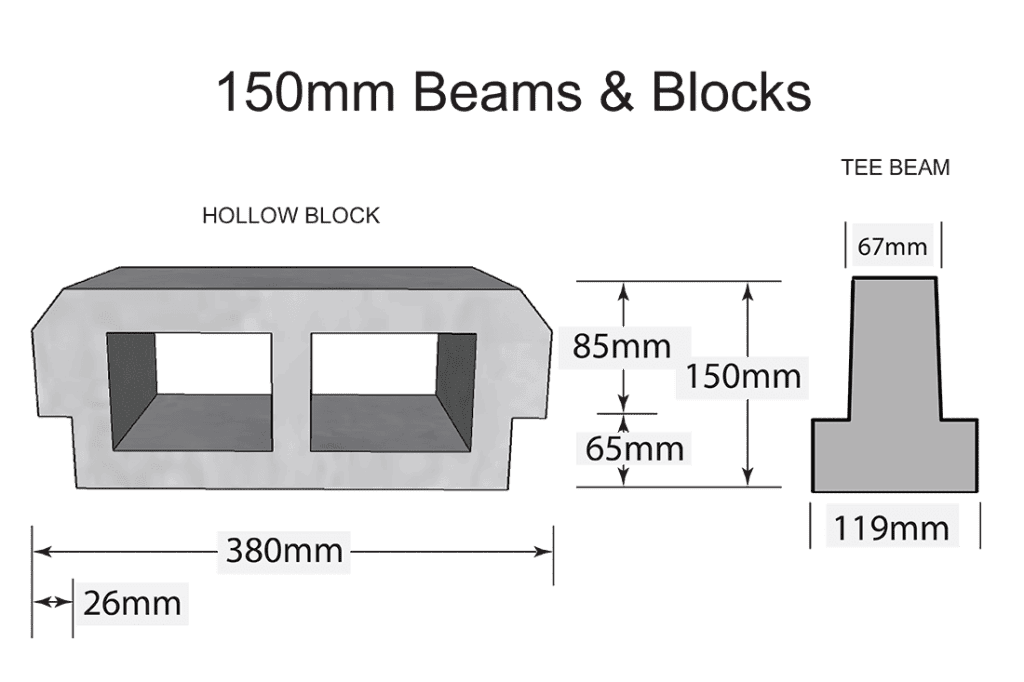

The precast concrete inverted T-beams are supported by the perimeter walls and internal load-bearing walls. The beams are

250mm in depth and made up to lengths of around 6m. They are usually designed and manufactured to span specific distances.

Beam arrangement and lengths are selected according to span and loading requirements, along with the type of block

specified.

Storied Slabs

Storied Slabs

The EcoConcrete Beam and Block Flooring System saves time and cost on site. The floor is quick to install without the need

for specialist skills. Site preparation is reduced and no hardcore or oversite concreting is required. Also, internal foundations allowing building works to continue without delay. The EcoConcrete Beam and Block Flooring System is ideal for a wide load applications and 225mm deep for heavy duty and longer span requirements, for example in commercial construction.

Roof Slab

Roof Slab

Flat roofs are becoming more and more desirable as they can typically be used in most housing projects, including commercial

and residential buildings. The quick turnaround coupled with cost-effectiveness means, you can benefit more from your

rooftops once it is completed. Beam and block flat roof slab systems are economical compared to other types of roofs. When

installed properly, beam and block flat roof slab system helps prevent leakages that occur along the valleys/ridges of a

pitched timber/steel roof. For starters, the roof is not completely flat as the name suggests but laid to a slight slope of 1:4 or

less, to ensure the rainwater drains well to the lower side. Then waterproofing is done to drain the rainwater well and avoid

leakage.

Where can Beam & Block be used?

Alternative uses of Beam & Block:

Septic Tank Cover Slab

Septic Tank Cover Slab

Septic tank slab systems are designed to collect, process, treat and dispose of household waste back to nature safely. This

treatment system is to avoid environmental pollution, which may lead to environmental-related diseases. Therefore, there is

a need to be extremely careful during the installation phase of the system to avoid any future complications.

Septic tanks cover slabs are usually very strenuous to construct. Preliminaries like shuttering and formworks have proven

hectic to put in place and later demolished. When using the beam and block slab system, the process has been made much

easier. The slab is suspended resting on the walls of the septic tank, no erecting and demolishing of the shutters and formworks.

Staircase

Staircase

A staircase using the beam and block is a fast and cost-effective way of construction.

One saves on the steelworks and formworks used in creating a support

base. The beams are laid on the ring beam creating a sloppy ramp, and mass

concreting of the steps is done.

Lintels

Lintels

Instead of the normal ‘’Koroga” to create a beam on top of a door or window, we

provide a precast prestressed beam that is already cured, fast, easy, and less

strenuous to install.

Tent Decks

Tent Decks

A tent platform keeps your tent off the damp ground, speeding up the drying

process of the canvas – discouraging the growth of mold in locations where the

sun has difficulties reaching.

Water Tank Tower Slab

Water Tank Tower Slab

A water tower slab is designed based on the loading’s expectations of the slab.

The beam arrangement of the beam and block slab is determined by the same

making it the ideal solution for your water tower.

Industrial Cold Storage

Industrial Cold Storage

Based on the specifications of cold storage units we engineer the slab using the

prestressed beams and Styrofoam in place of the infill block. Styrofoam is a type

of polystyrene, it is produced from polystyrene beads, which when expanded and

moulded under controlled conditions form a lightweight block.

What Our Clients say about Beam & Block:

Testimonials

Civil Engineer

Simon Maina

"I chose this precast slab because of time, and cost. We are saving a lot, especially on labour, and as we all know the rebars have gone up. I would recommend the use of prestressed beams and blocks in other projects. Other developers have come here, seen, and liked this technology because it makes a huge difference, what would take 30 days can be installed in less than a week."

Whar Our Clients Say

Contractor

Stephen Mwangi

"Personally, I like beam and block, I've used them in several projects because it is cheaper. Anyone in construction right now knows the prices of materials have shot up, and we all want to save in these hard times, especially on labour I save up to 20%."

Home Owner

John Mwicigi

It is my 1st time using beam and block, from the time I paid, to delivery, it took about 5 days because I was paying in instalments. I would say the system has worked well for me, and I can recommend it to someone else. The beams and the blocks are of good quality, they are quite firm, and I believe my house will be more stable.

Customer Stories:

Quantity Surveyor

Fidelis Mallon

“We are using beam and block in this project and despite the sudden changes in prices of steel and cement the price did not change from the time of quotation The time we estimated the cost for the conventional way the prices have changed I prefer Eco Concrete they send their technicians to work with us and leach our casual workers on this new technology.”

More Customer Stories:

Where has Beam and Block been used?

Case Studies on recent about the recent uses and applications of EcoConcrete Beam & Block in Kenya.

Case Study: The Strength of Block and Beam Flooring System

The Block and Beam flooring system has become increasingly popular in the construction industry due to its exceptional strength, durability, and efficiency. This case study focuses on the strength of

Case Study – Staircase with Beam and block

Beam and block staircases are a great option for anyone who wants a sturdy and versatile staircase that can be customized to their needs and preferences. They are easy to install, maintain, and repair, and they offer excellent performance and durability. If you are interested in using beam and block for your staircase project, contact us today for a free quote and consultation.

Case Study-Beam and Block with Precast Panels

The construction industry is rapidly changing to meet the needs of modern society, Beam and block precast slab provides a suitable, cost-effective, versatile, and safe way of slab construction.

Case study ground floor suspended slab

Beam and block allows major savings, especially on black cotton soil. No excavation or backfill, reduced labour, and equipment costs as all can be carried by hand. Reduced materials on-site also minimize security risks on cement and steel stored on site.

Case study – Flat roof installation in Joska

At EcoConcrete, we understand the challenges of protecting your flat roof slabs from the damaging effects of water. We also understand how important your property is

Case study – Beam and Block replacing steel decking.

beam and block precast slab used for upper floors offers a better, cost-effective and more efficient solution to both new and old builds

Case Study residential house in Ngong

The beam and block slab is fully suspended and rests on the ground beam, trench excavation for foundation walls only and suspend your slab above the ground. This allows massive savings on excavating and back-filling,

Case Study-CBC Additional Classes

Ecoconcrete has aided the Government of Kenya to deliver durable and cost-effective CBC classrooms in a timely manner ensuring the learner’s calendar was not compromised in any way.

Case Study – Eldoret Multi-Story Building

The use of Beam and Block on multi-story/commercial buildings is an ideal solution that ensures structural integrity. Precast is often stronger than cast-in-place concrete. Not only are they reinforced with steel rebar, but the controlled curing process also ensures that the concrete will set correctly under ideal conditions for maximized strength.

Case Study Archive:

Case Studies on recent about the recent uses and applications of EcoConcrete Beam & Block in Kenya.

Some of our other projects:

- Nanyuki Municipal Block (2017) -875 SM of ground floor slab

- Residential House in Kimende (2018-2019)– 2620 SM of Slabs

- Residential House in Kitengela (2018)- 630 SM of Ground floor and First floor Slabs

- Residential House in Ruiru (2019)- 421 SM of First floor and terrace

- Sports Hall for School in Lavington (2019)- 998 SM of Suspended Ground Floor

- School in Kemende (2018)

- Cottages in Diani(2018)- 530 SM of First floor and 470 SM of Roof Terrace

- Mezzanine Floor for Olesereni Hotel Nairobi (2018)- 300 SM

- Extension of Temple Slab (2019)- 70 SM

- Residential House Runda (2019)- 260 SM of First floor slab

- Nest, Mother and Babies (2019) -461 SM of suspended ground floor slab

- Residential House in Karen (2019)- 867 SM of slabs

- Godown in Industrial Area (2020) – 340 SM of slabs

- Residential House in Kwale (2020)- 785 SM of slabs

- Septic Tank in karen(2021) – 34M² of slab

- Kanninie mashion in Mlolongo(2021) – 602M² of ground slab

- Dan Thiongo residential house in Juja House (2021) – 139M² of slab

- Macways Supplies (2021) 320M² of slab

- Jyoti Hardware Extension (2021) – 499M² of slab

- Isiolo Reginal Hospital (2021) – 1965M² of slab

- Utawala Apartments (2021) – 168M² of slab

- Joska Apartments (2021) – 485M² of slab

- Garissa Mixed development (2021) – 453M² of slab

- AIPCA Dandora first floor installation (2021) – 300M² of slab

- Queen of apostles Roof Slab (2019) – 625 SM of Roof Slab

- Apartment in Konza City (2019-2020) – 839 SM of slab.

Construction Blogs

EcoConcrete Videos

EcoConcrete Beam & Block Videos

Sustainability

Beam & Block saves hundreds of trees on every build

EcoConcrete’s Beam & Block requires no form-work or propping saving large amount of timber every time it is used on site. As it is also factory made it reduces on emissions from transportation and reduces on waste.

We Follow Best Practices

At EcoConcrete we are committed to keeping people healthy & safe. We do this by following all the best health and safety practices both in our yard and on site. We are also committed to sustainable manufacturing, doing our bit to reduce climate change.

- Sustainablility

- Project on Time

- Modern Technology

- Bespoke Designs

Request a Quote

Learn More From

Frequently Asked Questions

It is a concrete product; we follow the same building guidelines and rules of a conventional slab. We have several advantages over conventional slab when it comes to price and ease of installation etc. Once the floor is completed there is no physical or observable difference between the two. |

The beams are made of high tensile steel which are stretched, and then concrete is poured over. After setting, the mechanical force applied during casting is released thereby stressing the wires in the concrete beam thus, the concrete is now effectively in a state of compression. It is capable of counteracting tensile stress, such as load.

The system reduces construction costs whilst maintaining the client’s expectations and quality of work. The system is faster, cost-effective, with minimum labour, no shuttering is required when compared to the traditional slab.

We use of high-tensile steel which is equivalent to D-16 wires as reinforcement.

The Beams cost around 1,100/= per length metre. However, we require your drawings to give you the full cost. The actual cost varies and will be based on your drawings and technical requirements. Depending on the location transport charges also vary.

Yes, If you include savings made on preliminaries, speed of build, no formwork, reduced labour, reduction of the total number of delivery vehicles, space-saving on site, low-security risk, all-weather installation, no overtime required, guaranteed quality, Just in time delivery, for low-level housing units no mechanical lifting required, minimal excavation. No mixing on site, No curing, No redundancy requirement for mixers and poker vibrators.

We are located on the 5th floor of Doctors Park, 3rd Parklands avenue, next to AGA Khan Hospital. |

Yes, we would like to know when you want to visit so that we can arrange with the production manager regarding the same.