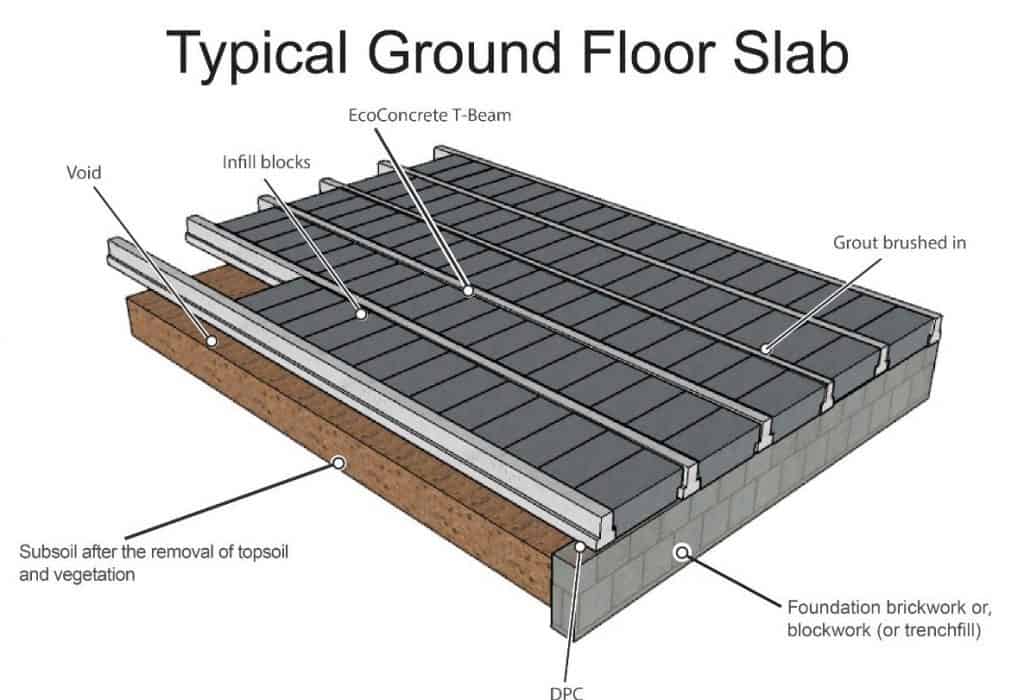

Installing a beam and block ground floor suspended slab is a straightforward process that saves you up to 20% of the overall slab cost. After site clearance, you will proceed to lay your foundations as normal. Whether you are doing a stone foundation or a ground column and ground beam design. There is no need for backfill or excessive excavation and cart away. Simply trench for the foundation walls and suspend the slab resting on the walls. A minimum void of 200mm is left underneath which creates ideal space to run services across the building as required. No need to run foul water piping externally, therefore, reducing manholes.

A Damp proof course layer is placed between the walling and the floor to prevent dampness from the foundation from being absorbed into the walls and floor. Once the services are laid a 50mm screed topping is poured over the slab and walling can begin.

About the project

The project is a two-story rental building covering approximately 300m2 on the ground floor and upper floors. Each floor has two houses, with one ensuite bedroom, fitted kitchen, and ample leaving and dining areas.

Construction commenced in early April 2023 and the estimated completion period is in October 2023 for both structural and interior. Currently, they are installing the beam and block ground floor suspended slab.

Clients’ dilemma

The area of construction was black cotton soil, considering the challenges of constructing on expansive soil textures our client hoped for a solution that would circumvent the challenges in a durable yet cost-effective way.

The time of construction was also an area of concern because he travels a lot and had little time to manage or oversee the project.

He learned about Ecoconcrete’s beam and blook through his neighbour who had used the system before and immediately knew it was the solution to use.

Solution by EcoConcrete

- We provided a cost-effective ground floor suspended slab that reduced the overall slab cost by 20%

- The installation of the slab was fast and easy providing an immediate working platform, and construction continued with no delays.

- There was no need for excessive excavation and backfill of the black cotton soil, only trenches for the foundation walls.

- We provided a durable and long-lasting slab solution that would go through years of wear and tear while still maintaining its structural integrity.

Conclusion

Beam and block slab allows major savings, especially on black cotton soil. No excavation or backfill, reduced labour, and equipment costs as all can be carried by hand. Reduced materials on-site also minimize security risks on cement and steel stored on site.