Technical FAQs

Load & Span Tables

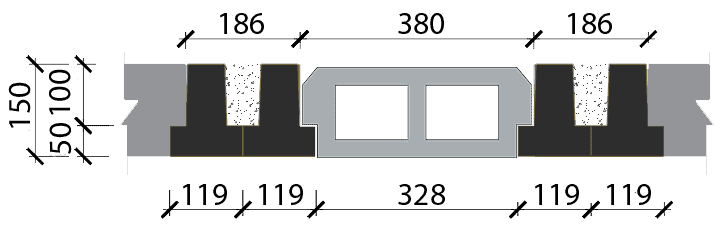

150mm Load Table

Density of Hollow Infill blocks = 1160Kg/m³, Topping (50mm)= 1.25KN/m2,

Celling plaster for suspended floor 12mm thick + tiles 18mm = 0.72KN/m2

| Beam - Block Types |  |  |  |

|

|---|---|---|---|---|

| Super Imposed Load | 1.5KN/m2 | 4.65 | 5.80 | 6.40 |

| 3.0KN/m2 | 4.40 | 5.50 | 6.10 | |

| 2.5KN/m2 | 4.20 | 5.30 | 5.80 | |

| 2.0KN/m2 | 4.05 | 5.05 | 5.60 | |

| 10.0KN/m2 | 3.75 | 4.70 | 5.20 | |

| 7.5KN/m2 | 3.50 | 4.40 | 4.90 | |

| 5.0KN/m2 | 3.07 | 3.75 | 4.30 | |

| 4.0KN/m2 | 2.75 | 3.40 | 3.80 | |

Residential houses = 1.5KN/m2, Hotels = 2.0KN/m2, Classrooms = 3.0KN/m2,

Shops = 4.0KN/m2, Workshops = 5.0KN/m2; Industrial walkways = 7.5KN/m2

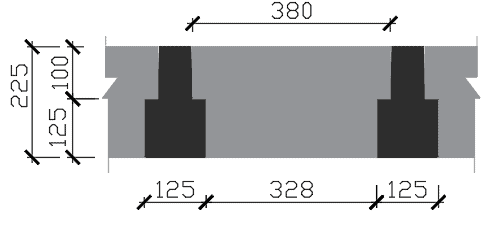

225mm Load Table

Density of Hollow Infill blocks = 1160Kg/m³, Topping (50mm)= 1.25KN/m2,

Celling plaster for suspended floor 12mm thick + tiles 18mm = 0.72KN/m2

| Beam - Block Types |  |  |

|

|---|---|---|---|

| Super Imposed Load | 1.5KN/m2 | 6.50 | 8.00 |

| 2.0KN/m2 | 6.25 | 7.70 | |

| 2.5KN/m2 | 6.00 | 7.40 | |

| 3.0KN/m2 | 5.70 | 7.10 | |

| 4.0KN/m2 | 5.40 | 6.70 | |

| 5.0KN/m2 | 5.10 | 6.30 | |

| 7.5KN/m2 | 4.50 | 5.60 | |

| 10.0KN/m2 | 4.00 | 5.00 | |

Residential houses = 1.5KN/m2, Hotels = 2.0KN/m2, Classrooms = 3.0KN/m2,

Shops = 4.0KN/m2, Workshops = 5.0KN/m2; Industrial walkways = 7.5KN/m2

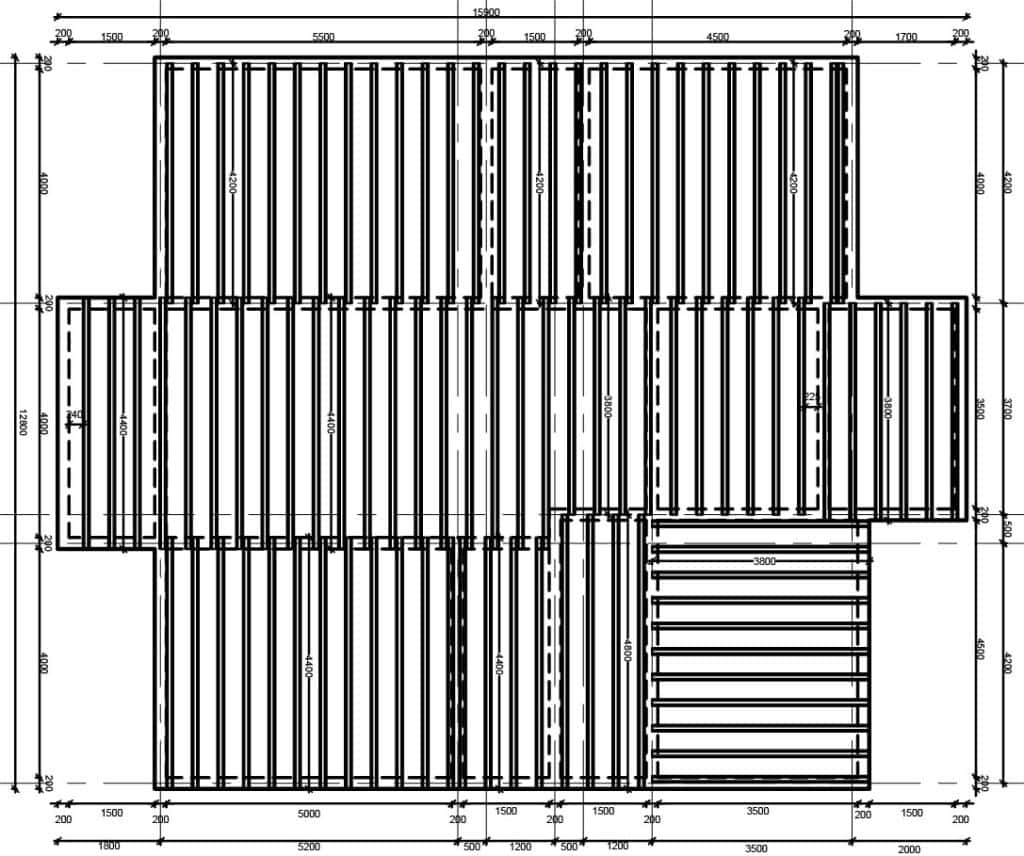

Typical Beam Plan:

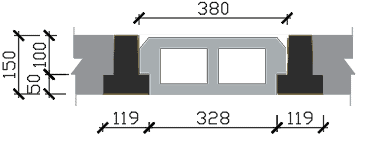

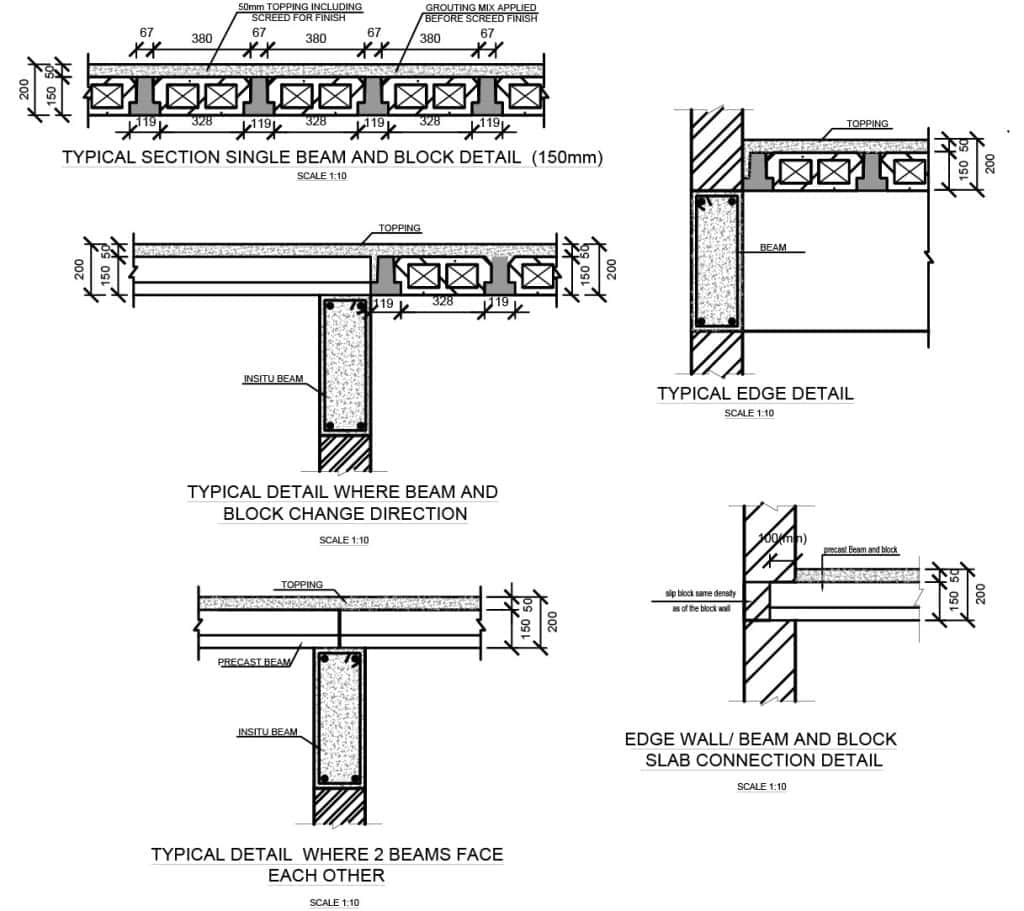

Typical Beam & Block Sections:

Quality Control

EcoConcrete ensures the high quality of its Beam and Block products through a meticulous quality control process. The process begins with the careful selection of raw materials, sourced sustainably to meet stringent environmental standards. Each phase of production is closely monitored, from the casting of concrete beams to the creation of concrete blocks.

The company employs advanced testing methodologies to assess the structural integrity, durability, and load-bearing capacities of its Beam and Block products. This includes rigorous testing for compressive strength, dimensional accuracy, and adherence to industry specifications. EcoConcrete’s quality control measures extend to the curing and finishing stages, ensuring that the final products meet or exceed industry standards for safety and performance.

Moreover, EcoConcrete places a strong emphasis on environmental sustainability throughout its manufacturing process. The materials used in Beam and Block production are chosen with eco-friendly considerations, aligning with the company’s commitment to reducing its ecological footprint.

To further enhance quality assurance, EcoConcrete employs skilled technicians who conduct regular inspections and quality checks. This comprehensive quality control process guarantees that each Beam and Block product leaving the EcoConcrete facility is of the highest quality, providing customers with reliable and durable solutions for their construction needs.

Our Quality Control Process

EcoConcrete conducts thorough inspections of all raw materials, including aggregates and concrete mix components, to guarantee they meet stringent quality standards. This step ensures the foundation for a robust and durable Beam and Block slab.

The concrete mixing process is closely monitored to achieve the precise composition required for optimal performance. Advanced mixing technologies are employed to ensure homogeneity and consistency in every batch.

During the casting phase, meticulous attention is given to the placement of beams and blocks within the mold. EcoConcrete utilizes advanced casting techniques to create slabs with uniform dimensions, minimizing variations and ensuring structural integrity.

The curing process is carefully controlled to allow the concrete to achieve its designed strength. EcoConcrete employs industry best practices in curing conditions, optimizing the slab’s durability and load-bearing capabilities.

After curing, each Beam and Block slab undergoes a thorough inspection for surface finish quality. This ensures a smooth and even surface, meeting aesthetic requirements and providing a superior base for subsequent finishes.

EcoConcrete places a strong emphasis on dimensional accuracy. Each slab is measured against precise specifications, and any deviation from these standards is meticulously addressed to guarantee that every product meets the required dimensions.

To verify the structural integrity and load-bearing capacity of each Beam and Block slab, EcoConcrete conducts comprehensive strength and load tests. This step ensures that the slabs meet or exceed industry standards for safety and performance.

Throughout the entire process, comprehensive quality assurance documentation is maintained. This includes records of raw material testing, production parameters, inspection results, and test certifications, providing transparency and traceability for every slab produced.

Precast Concrete Slab – Quality Assurance

How strong is the beam and block flooring system? In short, it is strong. The answer lies in both the tensile and compression strength and the curing process. Because our products are manufactured at our production yard, challenges that can affect the quality of our products during productions are avoided. The strictly controlled environment allows us to avoid these challenges, the most obvious ones being the temperature and weather.

Earthquake-Resistance

EcoConcrete Beam and Block Slab for Earthquake-resistant Structures.

This article focuses on the practicality of Eco-concrete beam and block slab use on multistorey buildings while addressing earthquake resistance concerns raised within the construction industry.

Is building with earthquake resistance necessary in Kenya

Tens of thousands of earthquakes happen globally every year. How can you build an earthquake-resistant structure?

Request a Quote

Learn More From

Frequently Asked Questions

It is a concrete product; we follow the same building guidelines and rules of a conventional slab. We have several advantages over conventional slab when it comes to price and ease of installation etc. Once the floor is completed there is no physical or observable difference between the two. |

The beams are made of high tensile steel which are stretched, and then concrete is poured over. After setting, the mechanical force applied during casting is released thereby stressing the wires in the concrete beam thus, the concrete is now effectively in a state of compression. It is capable of counteracting tensile stress, such as load.

The system reduces construction costs whilst maintaining the client’s expectations and quality of work. The system is faster, cost-effective, with minimum labour, no shuttering is required when compared to the traditional slab.

We use of high-tensile steel which is equivalent to D-16 wires as reinforcement.

The Beams cost around 1,100/= per length metre. However, we require your drawings to give you the full cost. The actual cost varies and will be based on your drawings and technical requirements. Depending on the location transport charges also vary.

Yes, If you include savings made on preliminaries, speed of build, no formwork, reduced labour, reduction of the total number of delivery vehicles, space-saving on site, low-security risk, all-weather installation, no overtime required, guaranteed quality, Just in time delivery, for low-level housing units no mechanical lifting required, minimal excavation. No mixing on site, No curing, No redundancy requirement for mixers and poker vibrators.

We are located on the 5th floor of Doctors Park, 3rd Parklands avenue, next to AGA Khan Hospital. |

Yes, we would like to know when you want to visit so that we can arrange with the production manager regarding the same.