Self-Build

Where can I use Beam and Block ?

Featured Article

How to build with Beam & Block

- Self-Build, by Gerald Taylor

Whether this is your first project or you are an experienced builder looking to try something new (and much quicker) Beam and Block can be the right solution for you. Here is a simple step by step guide to using the Ecoconcrete Beam & Block system. Read More…

- Step by Step Guide

- Timings Explained

- Clear Procedure

- Your Questions Answered

Our Construction Blog:

Features and articles about the uses and applications of EcoConcrete Beam & Block and construction in Kenya.

Simple Flooring Solutions: Exploring Beam and Block Slabs

Welcome to an insightful exploration of a versatile and eco-friendly flooring solution: Beam and Block Slabs. In the search for affordable construction practices, these slabs emerge as a key solution,

Diaspora Building – Depreciation of the Kenyan Shilling

The recent depreciation of the Kenyan Shilling (KES) against major currencies has stirred discussions about its impact on various aspects of the economy. For Kenyan expatriates residing in the USA

Shutter-Free Methods for Sustainable Building

In a paradigm shift for the construction industry, innovative methods are emerging that eliminate the need for traditional shuttering in crucial structural components like slabs, columns, and ring beams. These

All-Weather Construction with Precast Beam and Block

Precast beam and block construction is a proven and reliable flooring system that offers many advantages over conventional cast-in-place concrete slabs.

UN-Habitat Assembly 2023 on Sustainability

A big part of overall sustainability includes the long-established principles of reduction, reuse, and recycling. Precast concrete beam and block perfectly encapsulate sustainability.

Why choose EcoConcrete Beam and Block on Off-Plan Development

EcoConcrete Beam and Block precast slab system in off-plan developments emphasizes efficiency, versatility, and sustainability.

EcoConcrete Beam and Block Slab for Earthquake-resistant Structures.

This article focuses on the practicality of Eco-concrete beam and block slab use on multistorey buildings while addressing earthquake resistance concerns raised within the construction industry.

Cost Comparison Between Ecoconcrete Beam and Block vs Traditional Slabs

When constructing a building, the choice of flooring system can have a significant impact on the overall cost of the project. In this article, we’ll examine the differences between traditional and beam and block floor slabs and provide a detailed analysis of the costs associated with each.

Beam and block flat slab and waterproofing.

Beam and block flat roof slab system is economical compared to other types of roofs like the pitched timber roof. Since commercial structures are huge properties, expect to save more when using this system than other roofing types and materials.

Budget control in construction

Precast concrete is one of the versatile and modern ways to enhance the durability of construction in a cost-effective way. Precast concrete products have several benefits that tend to save time and money

Why use beam & block floor/roof slabs

A big part of overall sustainability includes the long-established principles of reduction, reuse, and recycling. Precast concrete beam and block perfectly encapsulate sustainability.

Saving in construction with beam and block

Precast concrete beam and block is a versatile and cost-effective construction material used in residential, commercial, and industrial applications.

CBC SCHOOL CONTROVERSY

Ecoconcrete has aided the Government of Kenya to deliver durable and cost-effective CBC classrooms in a timely manner ensuring the learner’s calendar was not compromised in any way.

ASSORTED USES OF BEAM AND BLOCK SLAB

Use of beam and block suspended concrete floor construction is increasingly the most common flooring system in today’s construction industry.

RISING COST OF ESSENTIAL PRODUCTS IN CONSTRUCTION

Are you looking into construction, and worried about the rising cost of essential materials? Consider EcoConcrete suspended floor/roof slab,

Structural infill block and Beam slab

Did you know that if you are building a beam & block slab, a non-structural block can pose a risk to your build? Non-structural infill blocks crush when a load is applied to them, especially a load dropped from a height or screed/topping/floor finishes e.g., Tiles.

NANYUKI township MT KENYA REGION

Did you know that you can save up to 50% of the overall slab cost by using the beam and block slab solution on black cotton soil? Imagine in this tough economy saving on excavation and backfilling costs as well as reduced time on your construction site.

FREE STRUCTURAL AUDIT ON YOUR BUILD

Did you know that poor structural integrity and insufficient safety measures can have disastrous consequences, including the collapse of a building, loss of life, and monetary losses? EcoConcrete offers structural audits to ensure that your residential, or commercial properties are safe, adhere to relevant codes, and present no danger during construction and while in use.

KITENGELA TOWNSHIP KAJIADO COUNTY

Kitengela is often described as “the best of both worlds” for its closeness to Nairobi, rural feel, affordable land, as well as collaborative and friendly nature of its residents. It is one of the fastest-growing areas according to the 2019 census. Its population has tripled since 2009. Its quick expansion is attributed to a massive influx of middle-class people.

COST OF DELAY IN CONSTRUCTION

In construction, people may argue that control is an elusive concept because of the many unforeseen circumstances that occur due to inflation and unreliable vendors who underdeliver. Ecoconcrete beam and block precast slab is changing the narrative by allowing contractors/project owners more control over their construction schedules and budget.

CLIENTs STORIES

We’re using beam and block because it is fast, we do not need to cut down a whole forest for support. If you do it the normal way of putting concrete slabs, you’ll need 300 – 500 trees for support, so we decided to go Eco green use beam and block, put it up, and continue construction the next day.

BEAM AND BLOCK JUST-IN-TIME DELIVERY

The ultimate goal of every construction project is to remain on scope, within the budget, and timelines. This requires a professional review of every aspect of the construction project. Ecoconcrete’s floor/roof slab is ready for collection. A cost effective solution that is fast and easy to install with minimal unskilled labour, providing an immediate working platform, No waiting periods no delays. Save both time and money while you’re at it.

Tribute to the late President Mwai Kibaki

The Ecoconcrete Team wish to offer sincere condolences to the family of the late former president of the Republic of Kenya, His Excellency President Mwai Kibaki and the entire Nation at large. An astute statesman has rested, but his accomplishments live on.

https://www.ecoconcrete.co.ke/ looks at how Kibaki’s legacy looms large in infrastructure

precast Slab: the present & future of slab construction?

The precast concrete slab is a reinforced concrete flooring system that combines ease of construction with structural integrity on your build. The method involves pouring higher strength concrete into a mould while under highly supervised conditions. The procedure prevents environmental variables from affecting the concrete and enhances the strength of the structures that use it. Where other materials would degrade, the precast concrete strengthens with age. It is highly resistant to potential environmental dangers and other elements. Moreover, concrete slabs require less labour, which saves the builder unnecessary labour costs, especially during slab construction.

Why do you need a structural engineer for your construction project?

To ensure public safety, all building projects in the country must adhere to the building and safety guidelines in the country that dictate all projects. Depending on the building standards, building codes can be used to estimate the weight of the building, and how it can withstand the effects such as earthquakes, floods, wind or even imposed loads.

in-situ concrete slab casting Cost: do you get the value for your money

Although preferred by many, the conventional slab construction method can be very challenging, especially when it comes to the cost estimation of your slab. The quotation procedure can be very tricky, plus do you get the value for your money?

Precast Concrete Slab – Quality Assurance

How strong is the beam and block flooring system? In short, it is strong. The answer lies in both the tensile and compression strength and the curing process. Because our products are manufactured at our production yard, challenges that can affect the quality of our products during productions are avoided. The strictly controlled environment allows us to avoid these challenges, the most obvious ones being the temperature and weather.

how to get a quotation: 5 Key Factors we consider

Getting a quotation for your project is one of the most essential processes when planning a project. Your project cost estimate consists of all expenditures, including site preparation, getting plans, and approvals, constructing and landscaping and finishing touches, which means the client can utilize this important aspect of construction from the initial stages of the project until the end. The procedure is almost the same when seeking a quotation for your floor as it is part of your construction project.

is the beam and block an eco-friendly construction component?

We have recently been getting a lot of questions on our Facebook page whether our beam and block flooring system is eco-friendly construction technology. the inquiries have since inspired this

Request a Quote

Learn More From

Frequently Asked Questions

It is a concrete product; we follow the same building guidelines and rules of a conventional slab. We have several advantages over conventional slab when it comes to price and ease of installation etc. Once the floor is completed there is no physical or observable difference between the two. |

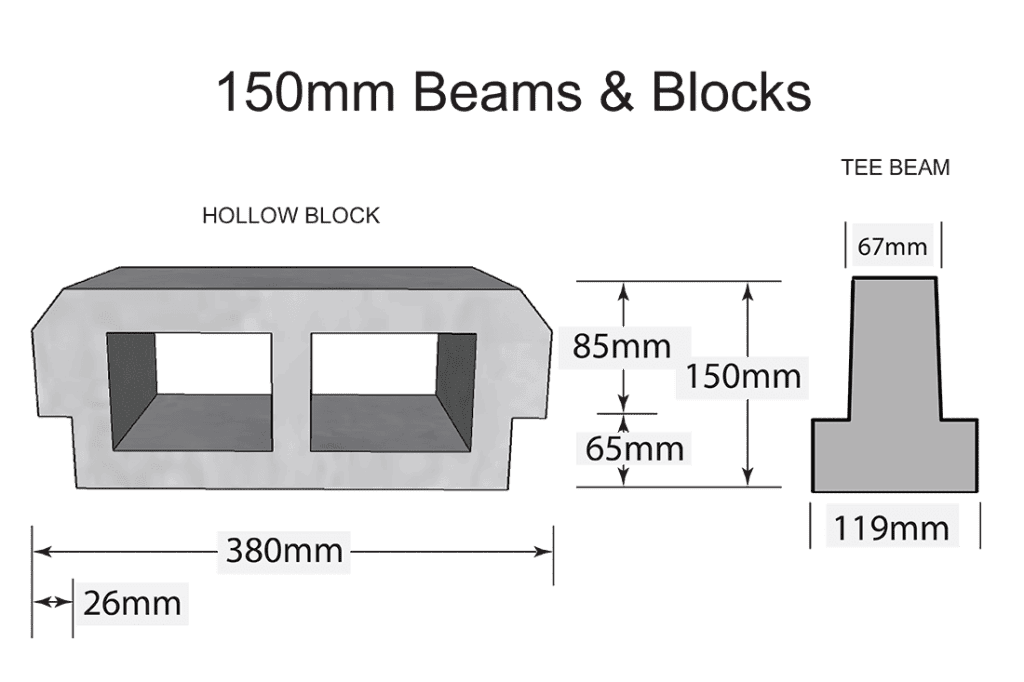

The beams are made of high tensile steel which are stretched, and then concrete is poured over. After setting, the mechanical force applied during casting is released thereby stressing the wires in the concrete beam thus, the concrete is now effectively in a state of compression. It is capable of counteracting tensile stress, such as load.

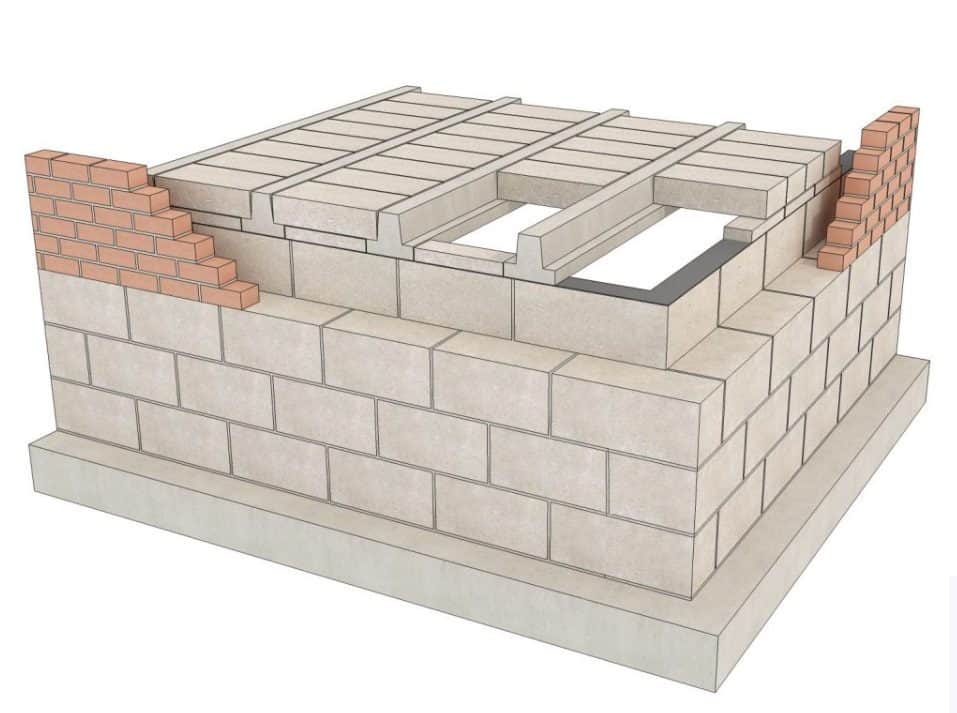

The system reduces construction costs whilst maintaining the client’s expectations and quality of work. The system is faster, cost-effective, with minimum labour, no shuttering is required when compared to the traditional slab.

We use of high-tensile steel which is equivalent to D-16 wires as reinforcement.

The Beams cost around 1,100/= per length metre. However, we require your drawings to give you the full cost. The actual cost varies and will be based on your drawings and technical requirements. Depending on the location transport charges also vary.

Yes, If you include savings made on preliminaries, speed of build, no formwork, reduced labour, reduction of the total number of delivery vehicles, space-saving on site, low-security risk, all-weather installation, no overtime required, guaranteed quality, Just in time delivery, for low-level housing units no mechanical lifting required, minimal excavation. No mixing on site, No curing, No redundancy requirement for mixers and poker vibrators.

We are located on the 5th floor of Doctors Park, 3rd Parklands avenue, next to AGA Khan Hospital. |

Yes, we would like to know when you want to visit so that we can arrange with the production manager regarding the same.