In these tough economic times the fluctuating prices of construction materials and inflation of the cost of living, have made people look for alternatives that allow them at least a little savings.

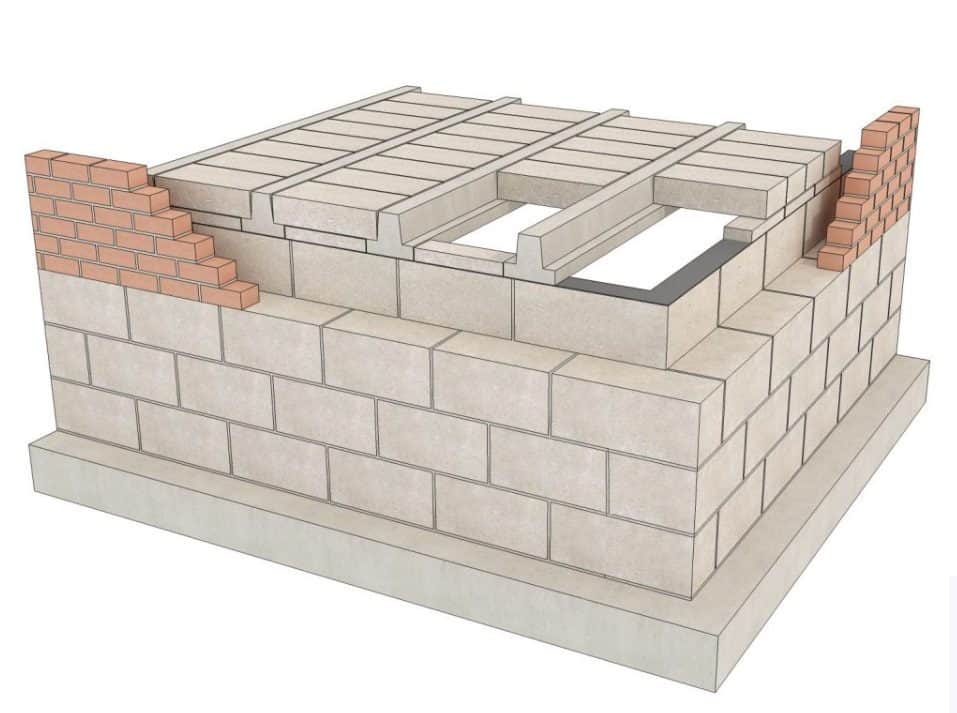

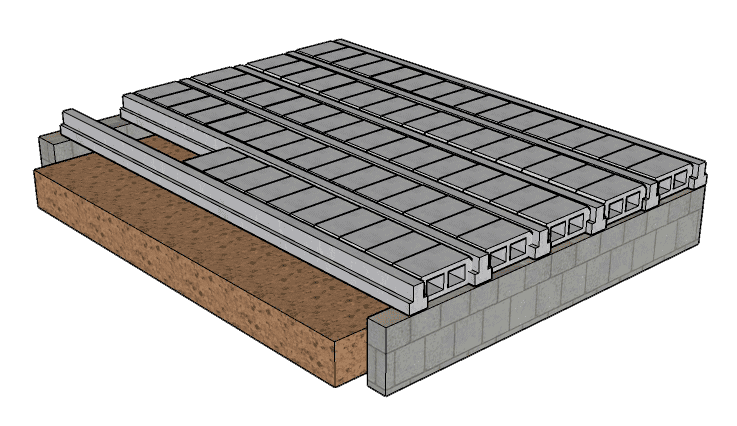

Precast concrete beam and block is a versatile and cost-effective construction material used in residential, commercial, and industrial applications and provides several benefits over traditional concrete casting.

Ways Precast Concrete Can Help You Save Money

1. Saves Time

When you’re in a rush, it’s hard to find materials that will help you get your project done quickly. Precast concrete can save time by allowing for faster installation and construction. In fact, precast concrete is used for projects that need to be completed quickly irrespective of their size or complexity (think residential homes and commercial buildings).

2. Energy Efficient

Precast concrete is a very energy-efficient material, so it will save you money on your heating and cooling bills. Not only that, but it can also reduce your carbon footprint, environmental impact, and waste—all of which add up to big savings for you over the long term.

3. Suitable for All Climates

Whether you live in a cold or hot climate, the precast concrete slab can withstand extreme weather conditions. One of the biggest benefits of using precast concrete is that it is not affected by extreme weather conditions. This makes it an ideal material for use in all-weather avoiding construction stalling to await favourable conditions.

4. Strength and Durability

Beam and block is a strong and durable slab that can be used in different types of construction projects. The beams are prestressed with high-tensile steel to increase the overall strength. Concrete has excellent strength, especially against fire, and mould. It also resists termites, wood-boring insects, and other pests. With minimal maintenance, precast concrete structures can last for decades! While still maintaining structural integrity. This saves you on repair costs.

5. Versatility

6. Cuts Labour Costs

Because precast beam and block is easy to install and requires little maintenance over time, you’ll save on labor costs compared with the traditional slab of mixing and casting concrete on site.

7. Lower Carbon Footprint Than Other Materials

Precast concrete is made from natural resources found in many places across the country. When you use beam and block, you’re using renewable resources instead of depleting your existing ones. Precast concrete also reduces the amount of energy needed to manufacture it because it does not require as much heat to produce.

8. Cuts Transportation Costs

By manufacturing precast concrete in a controlled environment out of site, you avoid the cost of transporting different materials and labor to make them. This helps you save money as well as preserve natural resources like fossil fuels for other uses.

9. Less Maintenance

Precast is often stronger than cast-in-place concrete. Not only are they reinforced with steel rebar, but the controlled curing process also ensures that the concrete will set correctly under ideal conditions for maximized strength resulting in a durable product.

10. Easy to Install

If you need a new structure built quickly by workers who are experts at what they do, precast is the way for you! The process takes less time than conventional construction methods like pouring concrete over site-made forms – which means less money spent overall during construction and less risk of delays due to weather conditions like rain.

Conclusion

The ultimate goal of every construction project is to remain on scope, within budget, and within timelines. To ensure that your construction project is within budget make sure to use precast, which often gives you a predetermined cost of construction. This in turn allows you more control over the project.

While we are all in search of cost-effective alternatives in construction we should always prioritize structural integrity to avoid unfortunate disasters and losses.

- Never Take Shortcuts – by law, geological surveys and soil testing should be done before planning the structure design. Taking shortcuts leads to inappropriate designs, erroneous calculations, and ultimately, structural failure.

- Use Quality Materials – Most construction projects have a set budget. But sometimes, to save on cost, the quality of materials is sacrificed. Substandard materials are called that for a reason. They didn’t pass quality inspections and are more likely to have less load-bearing strength than standard ones.

- Hire Professionals – Hiring certified and experienced professionals will save you from costly repairs. Plus, it will ensure the safety of whoever will occupy or use the structure.

Call us today on 0700326326 for a free quote and free structural audit of your build. A team of professionals you can trust.