Did you know that if you are building a beam & block slab, a non-structural block can pose a risk to your build? Non-structural infill blocks crush when a load is applied to them, especially a load dropped from a height or screed/topping/floor finishes e.g., Tiles.

The precast slab is a complete unit, it consists of prestressed beams and structural infill blocks which are an integral part of the slab. It is an engineered solution for loading spans and functionality of a specific building. This is why we normally advise our clients to purchase the slab as a complete unit, and not to outsource the blocks elsewhere. As a company we are sure of the complete design mix, production process, curing period, and the quality tests the precast undergoes, hence we can assure you of the quality of your build.

The infill blocks are made of concrete, the blocks are transverse load tested and capable of sustaining a central point load of 3.5kN. as per BS EN 771. A structural infill block can resist fire, therefore the minimal collapse of the slab after fire damage.

The infill blocks are adequately cured during manufacture and achieve significant strength before being transported to the site. A sharp sand cement mix/slurry of 3:1 should be brushed into the pre-wetted and cleaned blocks, ensuring all joints are properly filled.

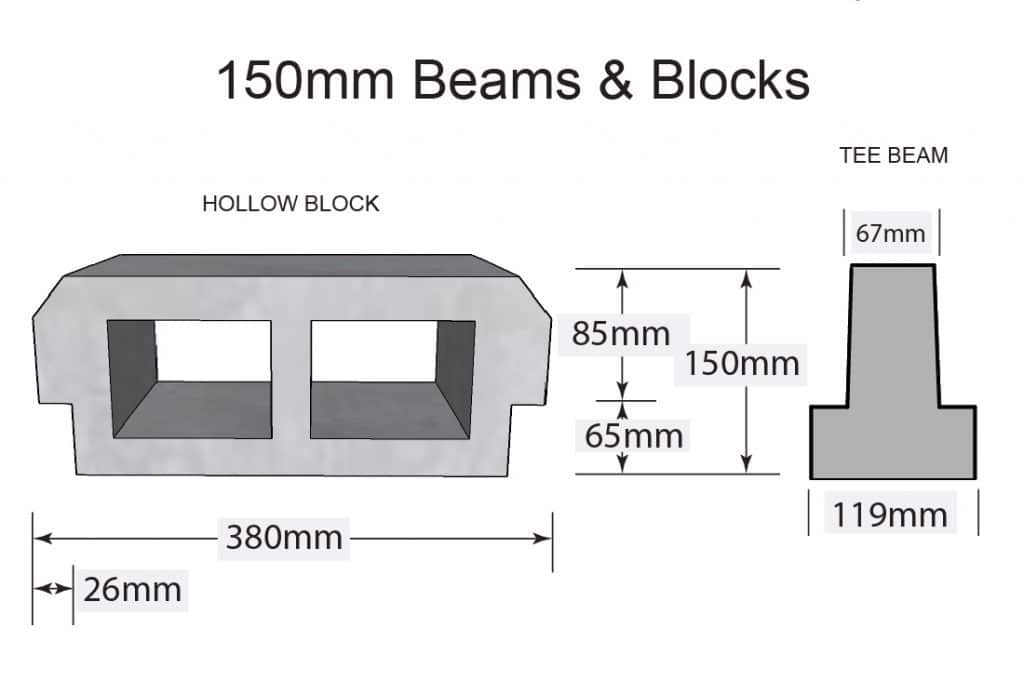

The infill hollow block and beam

Importance of structural integrity in construction

Structural integrity is the ability of an item, either a structural component or a structure consisting of many components to hold together under a load, including its own weight, without breaking or deforming excessively. It assures that the construction will perform its designed function during reasonable use, for as long as its intended life span.

Many aspects of our construction projects must be assessed by an engineer to ensure they are completed effectively. One of these aspects is structural integrity. Structural integrity entails the reliability of a structure or its structural components to support their weight and prevent deformation, breakage, and any catastrophic failure through their predicted building life. The structural integrity of a property, however, does not only rely on its general design. A property can retain its structural integrity if assessed and maintained periodically.

Main Causes of Structural Failure

The structural integrity of a building may depend heavily on its initial design and long-term upkeep. However, there are numerous reasons why the structural integrity of specific buildings tends to fail despite executing the initial design well and maintaining them effectively. Some of them are as follows:

- Weak or Defective Materials– One of the reasons why certain buildings have poor structural integrity is they are built out of weak or defective materials. When planning for a building structure, one component that contractors must consider heavily is the expected load of the property. Once the expected load is obtained, they must attain materials that can handle the obtained load value. Failure to do this will only result in a building that is bombarded with structural-related issues.

- Inappropriate Geometric Design– Another reason why structural failure happens to several properties is they maximize inappropriate geometric design. Opting for a good geometric design can save a structure and its structural components from corrosion, creep, fatigue, and wear. Alternatively, going for an inappropriate design will only result in structural deterioration, yielding damages that can be costly to repair. Worse, it might lead to the sudden failure of the building.

- Neglected Surrounding Elements– One more reason why buildings may have structural failure is due to negligence during their planning phase. Contractors, especially engineers, must assess the environmental considerations before crafting designs and processes that will make buildings durable and functional. Now, neglecting to mitigate environmental elements will only result in properties that have weakly supported structures.

- poor workmanship

- Inappropriate structural design

- Compromises in professional ethics for monetary gains

- Erroneous calculations

How do We Test Structural Integrity on the beam and block?

As mentioned, there are several factors that can affect a structure’s integrity. That’s why evaluating structural integrity involves applying various techniques that assure the integrity of products.

The tests the beams and blocks undergo include,

- penetration resistance test

- concrete resistivity test

- full-scale load test

- Cube testing

Conclusion

As EcoConcrete structural advice is an integral part of our sales process, before we supply you with the precast slab, we must ensure structural integrity. It is an often-overlooked factor in construction projects, and that’s why some structures fail to hold up to their purpose or stand the test of time. To ensure that your project or property is structurally stable, make sure to,

Never Take Shortcuts – by law, geological surveys and soil testing should be done before planning the structure design. Unfortunately, this doesn’t always happen in practice especially if the project has a tight deadline. Taking shortcuts lead to inappropriate designs, erroneous calculations, and ultimately, structural failure.

Use Quality Materials – Most construction projects have a set budget. But sometimes, to save on cost, the quality of materials is sacrificed. Substandard materials are called that for a reason. They didn’t pass quality inspections and are more likely to have less load-bearing strength than standard ones.

Hire Professionals – This is a no-brainer. Hiring certified and experienced professionals will save you from costly repairs. Plus, it will ensure the safety of whoever will occupy or use the structure.

Contact us today for the infill block and beam floor/roof slab solution that comes with value-added professional structural advice on your build. Let us all prioritize integrity in construction.

Call 0700326326