In Kenya, most people do not consider the risk of an earthquake due to the low chance of its occurrence in the region. The earthquake events in Syria and Turkey that caused large-scale destruction have shown the risks of earthquakes on buildings and infrastructure. We recently experienced mild tremors in April 2023, even though Kenya is categorized as a low earthquake zone. This article focuses on the practicality of Eco-concrete beam and block slab use on multistorey buildings while addressing earthquake resistance concerns raised within the construction industry.

In Kenya, earthquake design is a requirement for buildings above 5 floors high. Beyond this limit design for wind and earthquake loading is a necessity. Earthquake design focuses on the ability of a structural system to resist damage under extreme loads, termed the robustness of a structure. When precast elements are used in a structure there needs to be strong connections between the members to achieve robustness.

Earthquake load occurs due to the inertia force produced in the building from seismic excitations.

Inertia force varies with the mass, such that the higher mass of the structure will imply that the earthquake loading will also be high. The magnitude of earthquake loading depends upon the weight or mass of the building, dynamic properties of the building and difference in stiffness of adjacent floors along with the intensity and duration of the earthquake. When the earthquake load exceeds the moment of resistance offered by the element, then the structure will break or be damaged.

Ground shaking induces inertia forces in a building where mass is present. These inertia forces are transferred

downward through horizontally and vertically aligned structural elements to foundations, which, in turn, transmit these forces to the soil underneath. The paths along which these inertia forces are transferred through building are Load Paths.

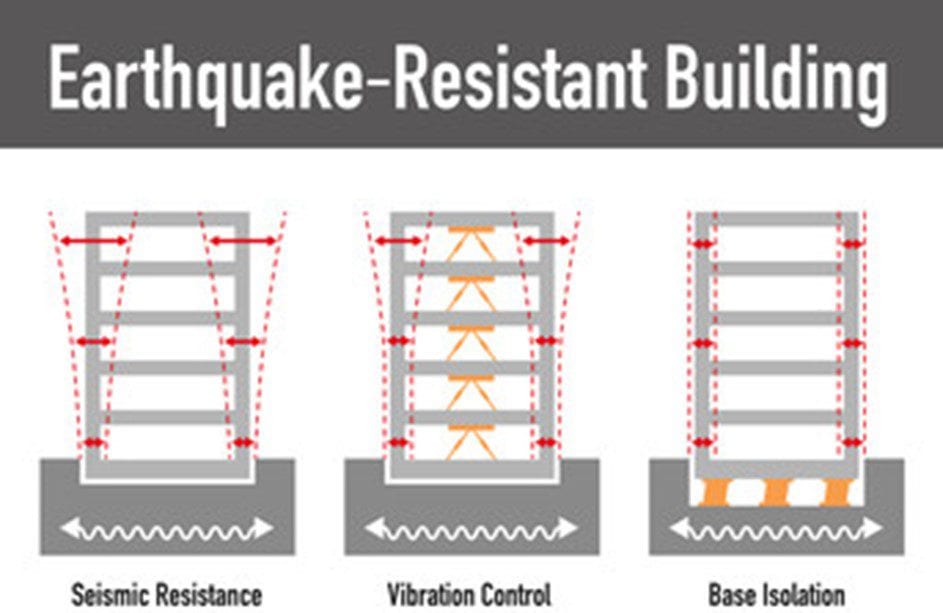

Earthquake Resistant Building and Structure

Buildings may have multiple load paths running between locations of mass and foundations. Load paths are as much a concern for transmitting vertical loads (e.g., self-weight, live load) as for horizontal loads (e.g., earthquake and wind).

Structural elements in buildings that constitute load paths include:

(a) Horizontal diaphragm elements laid in horizontal plane, i.e., roof slabs, floor slabs or trussed roofs and bracing.

(b) Vertical elements spanning in vertical plane along height of building, i.e., planar frames (beams and columns interconnected at different levels), walls (usually made of RC or masonry), & trusses.

(c) Foundations and Soils, Isolated and combined footings, mats, piles, wells, soil layers and rock.

(d) Connections between the above elements.

Earthquake loads on multistorey structures can be designed to follow load paths through the frame of the buildings and the shear walls. Horizontal floors can effectively resist and transfer earthquake forces through the direct load paths, therefore robust connections are needed between structural elements along the load path. Buildings can be designed to resist earthquakes by having moment-resisting frames where extra reinforcement is designed to take the horizontal loading.

Robust connections are needed between structural elements along load paths: In an earthquake-resistant structure, every connection is tested during strong earthquake shaking. These connections should be stiff and strong to offer continuous load paths without being damaged during strong earthquake shaking. The term robustness refers to the ability of a structural system to resist damage under extreme loads.

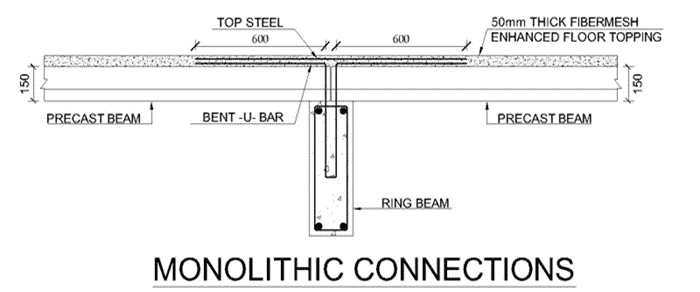

Monolithic Connection

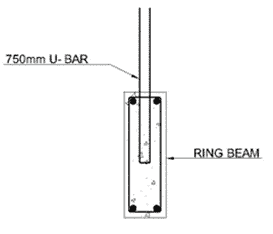

Monolithic connections refer to a system where reinforcement is continuous across the connection and anchored in the adjacent elements, then cast in place homogenously. This is to improve robustness in tall multistorey buildings susceptible to horizontal loads from seismic activity and wind. Reinforcement in supporting and supported members should be detailed to ensure proper anchorage between precast and in-situ structural elements.

For a monolithic connection between the in-situ beam and precast slab, anchor a bent U-shaped reinforced steel bar and cast simultaneously with the in-situ beams such that the bent reinforcement is projecting above the beam approx. 600mm. The precast beam and block slab is then supported over the in-situ beam and the projecting reinforcement is bent onto the precast slab on either side of the beam.

Top reinforcement is then laid across the in-situ beam and tied to the anchored reinforcement. Cast 50mm thick screed homogenously over the connection to have continuity between the in-situ beam and the precast slab.

Conclusion

Use of EcoConcrete beam and block on multi-storey structures designed for earthquake-resistant structures is feasible considering all the principles of earthquake design. Their efficiency, speed, design flexibility, structural performance, and sustainability attributes make them highly desirable for construction projects.