When constructing a building, the choice of flooring system can have a significant impact on the overall cost of the project. In this article, we’ll examine the differences between traditional and beam and block floor slabs and provide a detailed analysis of the costs associated with each. Whether you’re a builder, architect, or simply someone interested in construction, this post will give you valuable insights into the financial aspects of selecting a flooring system for your next project.

Construction Works Rates

The construction rates prepared by consultants are priced for projects with fully equipped contractors working on large projects. For Individual builders and small contractors, the cost ends up significantly higher as they must hire machinery, equipment and means of transport.

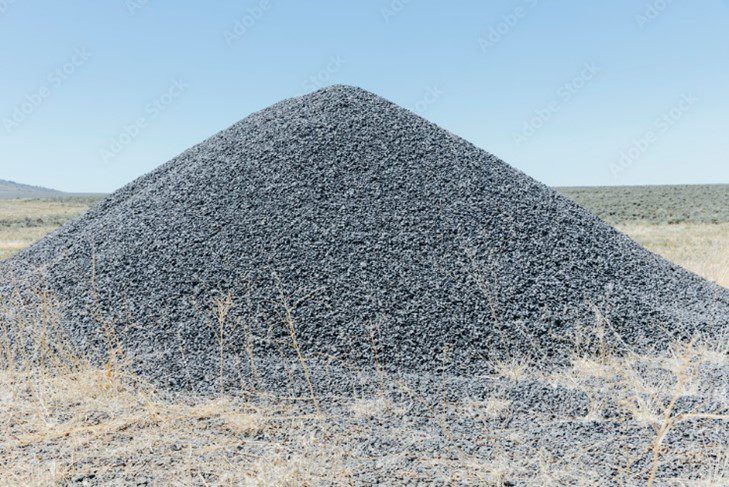

There is a high amount of wastage in traditional slabs construction, arising from stockpiling of materials in heaps. The bottom layer of the heaps is wasted from mixing with soil, organic matter, and rainwater runoff. The construction rates do not allow for this wastage which is considerable. Ecoconcrete Beam and Block slab has less wastage has fixed cost and no hidden costs as the slab are manufactured in a controlled environment therefore the quality is also guaranteed.

Transportation

On a slab of 100m2, using the precast option requires one 27-ton lorry to deliver to site. The traditional slab option requires one 27-ton lorry ballast, one 12-ton lorry sand and one 7-ton Cement lorries, one 7-ton lorry formwork, one 7-ton lorry concrete mixer, poker vibrators.

This difference arises from the multiple construction items transported separately in traditional slabs compared to precast. Also, since the construction materials don’t fill up the lorry capacity, more trips will be required.

Sites with black cotton soils

For construction of ground slabs on sites with black cotton soils, would involve excavation and disposal of the expansive soil. Followed by backfilling the excavated areas with non-expansive soils before construction.

Precast concrete use on ground slabs reduces the volume of earthworks on sites as excavation is limited to the load bearing walls and/or column footings. Ground slab of 100m2 with average 1.5m deep expansive soil, traditional slab requires 25 Trips while precast slab requires 5 Trips.

Storage Space Constraints

Traditional concrete works require a large space is required for stockpiling concrete material therefore for sites with limited space, execution is a challenge making the traditional option less cost effective. In such cases a precast slab is more practical as it is a ready slab and requires less space for storage.

Formwork Shuttering

Conventional slabs require formwork and propping to support the slab as the concrete cures. Set-up and erection of formwork is a costly and time-consuming exercise, it also involves skilled personnel comprising of masons, carpenters, steel fixers to execute. A curing period of at least 21 days for the concrete is required before stripping off formwork.

Ecoconcrete beam and block slab requires no formwork at all as the system is self-supporting, that is, the beams and blocks fit into each other. It does not require skilled labour to erect on site, therefore saving on cost of labor. The floor provides an immediate working platform allowing building works to continue without delay.

Comparison table

|

EcoConcrete beam and block slab |

Traditional slab |

|

1. Fixed cost (no wastage, theft) |

1. Variable cost (wastage, theft) |

|

2. Quality assured (factory produced) |

2. Quality variable depending on personnel skill |

|

3. No skilled labor required to execute |

3. Requires various skilled labor to execute |

|

4. Weather resistant |

4. Affected by weather |

|

5. No curing time, precast |

5. Requires minimum 21 days curing time |

|

6. Formwork shuttering not required |

6. Formwork shuttering required |

|

7. No propping required |

7. Propping required |

|

8. Low transportation cost |

8. High transportation cost |

|

9. Minimal Excavation and backfill works |

9. Large volumes of Excavation and backfilling works |

|

10. No steel reinforcement required |

10. Steel reinforcement required |

Conclusion

Ecoconcrete beam and block option has numerous benefits including, fixed cost, minimal wastage, lower cost of transportation, higher quality of concrete (produced in factory), suitable for sites with black cotton and with limited space.

Traditional slabs have a variable cost, high wastage, high cost of transportation, expensive on sites with black cotton soil, comparatively lower quality of concrete.