Suspended concrete floor construction is increasingly the most common flooring system in today’s construction industry. The beam and block precast slab solution has proved to be versatile adopting, to several different functions as it is engineered for specific building designs. They include.

- Ground floor slab

- Flat roof slab

- Septic tank cover slab

- Water tower slab

- Tent deck platforms

- An alternative to steel decking

- used as a Lintel

- High-rise buildings

- Industrial buildings

The beam and block slab system is an economical option due to the off-site manufacture of the beams and blocks, fast assembly, and little requirement for specialist labour. The installation of the floor is not usually weather dependent therefore specifying this form of construction can reduce site delays that other methods might encounter.

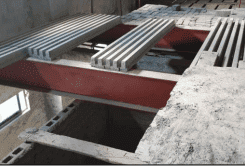

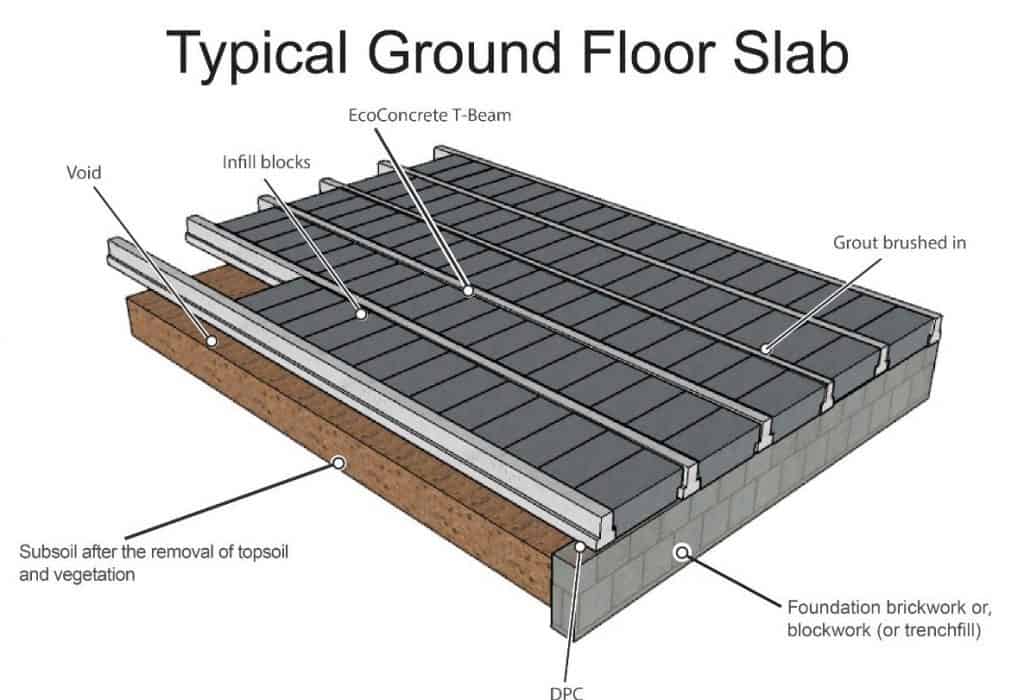

1. Ground Floor slab

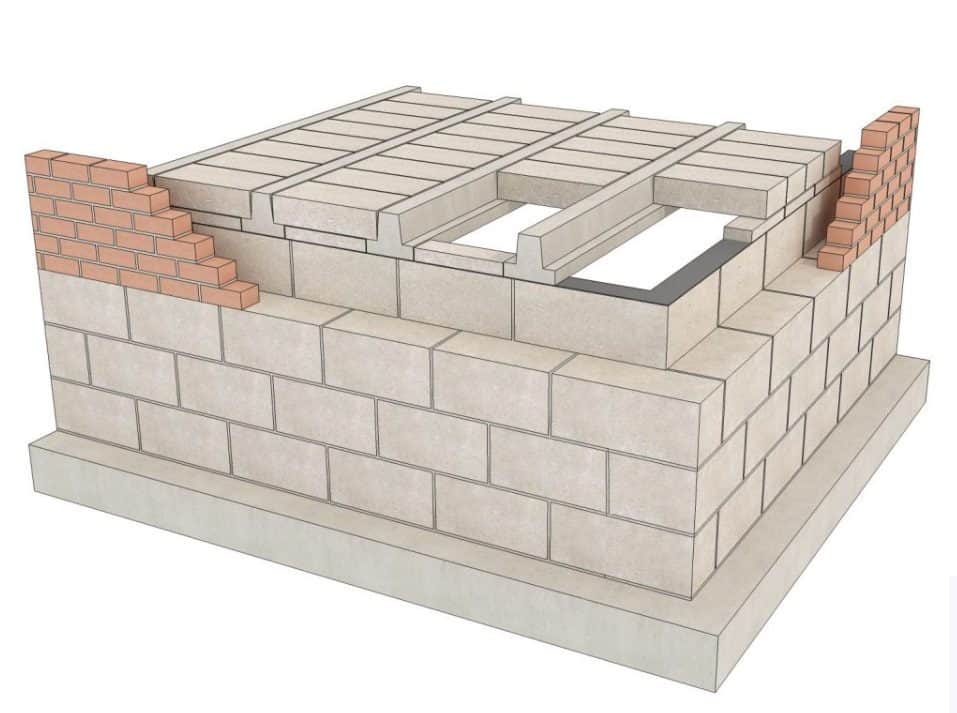

For the ground floor slab, there is no need for mass excavation, simply remove the topsoil and trench for the foundation walls. The precast concrete inverted T-beams are supported by the perimeter walls and internal load-bearing walls. The beams are 250mm in depth and made up to lengths of around 6m. They are usually designed and manufactured to span specific distances. Beam arrangement and lengths are selected according to span and loading requirements, along with the type of block specified.

Infill blocks are then positioned between the T-beams, these blocks are usually lightweight concrete. A sand and cement grout mixture is brushed over the surface, filling any gaps providing a good load distribution, and avoiding movement in the blocks. The grout also keeps insects and vermin out and assists with air tightness.

For areas with expansive soil textures like black cotton, the same procedure applies as there is no mass excavation or backfilling needed. You simply leave the soil intact and build above it. Trench for foundation walls only, raise the foundation walls, cast the ring beam, and suspend the slab to rest on the ring beam or foundation walls.

A void of at least 150mm is left between the soil and the underside of the slab. If heavy clay soil is present it is good practice to increase the void depth to as much as 225mm or possibly more. All organic material must be removed from the soil and the surface should be treated with weedkiller.

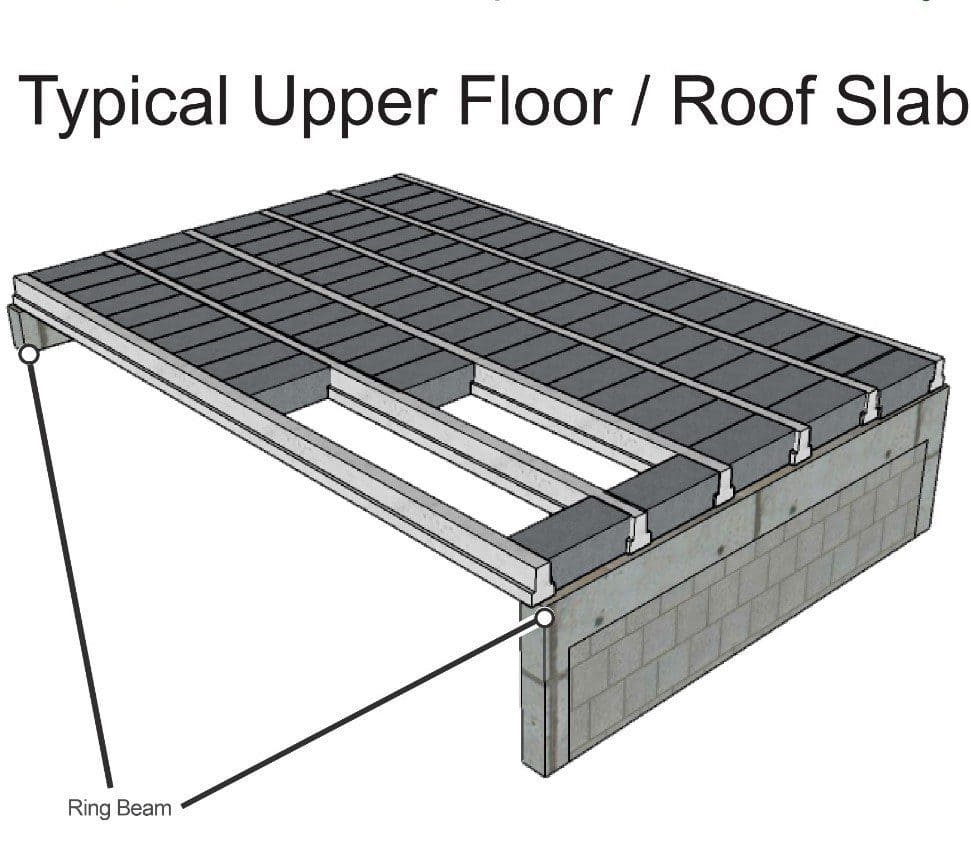

2. Roof slab

Flat roofs are becoming more and more desirable as they can typically be used in most housing projects, including commercial and residential buildings. The quick turnaround coupled with cost-effectiveness means, you can benefit more from your rooftops once it is completed.

Benefits of beam and block system on flat roofs

Cost-efficient

Beam and block flat roof slab systems are economical compared to other types of roofs. Since commercial structures are huge properties, expect to save more when using this system than other roofing materials.

Prevent leakages.

When installed properly, beam and block flat roof slab system prevents leakages that occur along the valleys/ridges of a pitched timber/steel roof. For starters, the roof is not completely flat as the name suggests but laid to a slight slope of 1:4 or less, to ensure the rainwater drains well to the lower side. Then waterproofing is done to drain the rainwater well and avoid leakage.

Extra working space for various functions

The use of beam and block flat roof slabs has begun to be popular because of the flexibility to use it as a working space, temporary shelter, rooftop garden, or till a future vertical extension is taken place. You can easily convert your beam and block flat roof into a drying yard, a resting area, or a storage area.

Low Maintenance

Another humanistic advantage of the roof is maintenance. After some time, it may accumulate moulds, debris dirt, stains, and other external elements. However, occasionally, you can remove these things from the surface using professional services. Some may also opt to do it by themselves, but while this may be guidance from the experts is imperative. It makes them to make the procedure a success.

3. Septic tank cover slab

Septic tank slab systems are designed to collect, process, treat and dispose of household waste back to nature safely. This treatment system is to avoid environmental pollution, which may lead to environmental-related diseases. Therefore, there is a need to be extremely careful during the installation phase of the system to avoid any future complications.

Septic tanks cover slabs are usually very strenuous to construct. Preliminaries like shuttering and formworks have proven hectic to put in place and later demolished. When using the beam and block slab system, the process has been made much easier. The slab is suspended resting on the walls of the septic tank, no erecting and demolishing of the shutters and formworks.

4. Water tank tower slab

A water tower slab is designed based on the loading’s expectations of the slab. The beam arrangement of the beam and block slab is determined by the same making it the ideal solution for your water tower.

5. Highrise/commercial buildings

Precast Beam and Block slab on Highrise/commercial buildings is an ideal solution that ensures structural integrity.

Precast is often stronger than cast-in-place concrete. Not only are they reinforced with steel rebar, but the controlled curing process also ensures that the concrete will set correctly under

ideal conditions for maximized strength. This assures the structural integrity of your multistorey/commercial building. On matters of cost, there are massive savings on labour and materials used.

6. Staircase

A staircase using the beam and block is a fast and cost-effective way of construction. One saves on the steelworks and formworks used in creating a support base. The beams are laid on the ring beam creating a sloppy ramp, and mass concreting of the steps is done.

7. beams used as a lintel (Alternative casting)

Instead of the normal ‘’Koroga” to create a beam on top of a door or window, we provide a precast prestressed beam that is already cured, fast, easy, and less strenuous to install.

8. Beam and block used as tent decks.

A tent platform keeps your tent off the damp ground, speeding up the drying process of the canvas – discouraging the growth of mold in locations where the sun has difficulties reaching.

The platform also helps to encourage air circulation around the lower walls and the floor to help dry out damp canvas. The beam and block slab provides a perfect solution for tent decking as it is fast and easy to install providing a solution that can be dismantled and reused for temporary and permanent tent setups.

9. Industrial cold storage floors using prestressed beams and polystyrene.

Based on the specifications of cold storage units we engineer the slab using the prestressed beams and Styrofoam in place of the infill block. Styrofoam is a type of polystyrene, it is produced from polystyrene beads, which when expanded and moulded under controlled conditions form a lightweight block. It is made mostly of air, meaning it is a poor conductor of heat, but an excellent convector. It traps the air in small pockets, blocking the flow of heat energy. This reduces both conduction and convection and makes Styrofoam a good insulator.

After installation of the beams and Styrofoam, a structural topping will be cast.

Advantages of using the beam and Styrofoam

1. Excellent compressive strength characteristics.

precast prestressed beams reduce the volume of concrete required in construction, lowering the use and transportation of materials such as steel, cement, and aggregate. It also boosts the durability and service life of the slab. Concrete is intrinsically resistant to compressive stresses, but its resistance to tension is much lower. Strength and durability are the basic requirements of prestressed concrete. The prestressing levels are determined in such a way that the structural member shows desired performance safely and economically.

2. Insulation against set temperature losses.

Styrofoam sheets are made mostly of air, meaning it is a poor conductor of heat, but an excellent convector. It traps the air in small pockets, blocking the flow of heat energy. This reduces both conduction and convection and makes Styrofoam a good insulator.

3. No excavation and backfilling costs

There was no mass excavation and backfilling of the black cotton soil. The slab was suspended above the ground, only trenches for the foundation walls were dug, foundation walls were raised, and the beams were suspended on the ring beam.

4. Self-supporting properties.

Light Weight, expanded Styrofoam is extremely lightweight, making it ideal for transport and installation.

Moisture Resistant – Styrofoam is resistant to water and moisture. This means that it does not absorb them and that its insulating performance is not compromised when in contact with these elements.

Durability.

Thermal Efficiency.

Versatility.

On-Site Ease of Use.

Environmental Sustainability.

10. Steel decking

Steel decking is mostly done for mezzanine floors, it is also known as metal decking, which is a sheet of high-performance galvanized steel used in the construction of composite concrete floor slabs. It can also be used as a structural feature in roof construction. When specified as metal roof decking it is used to support insulating membranes.

Instead of the process of laying sheets of mesh grid reinforcement, fixing over the metal decking, pouring concrete, and screeding on top to create a composite concrete floor slab, the beam and block slab system is much durable and faster to install and screed.