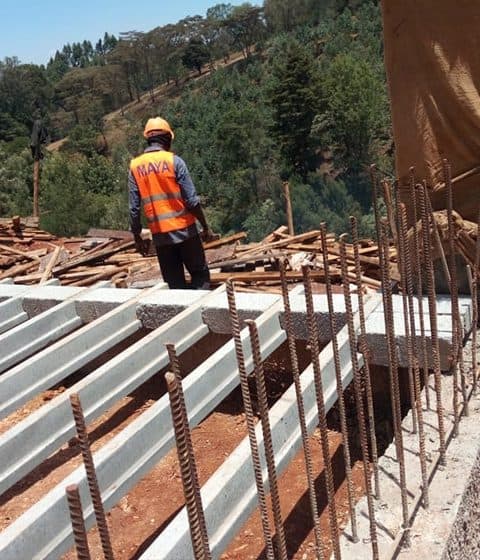

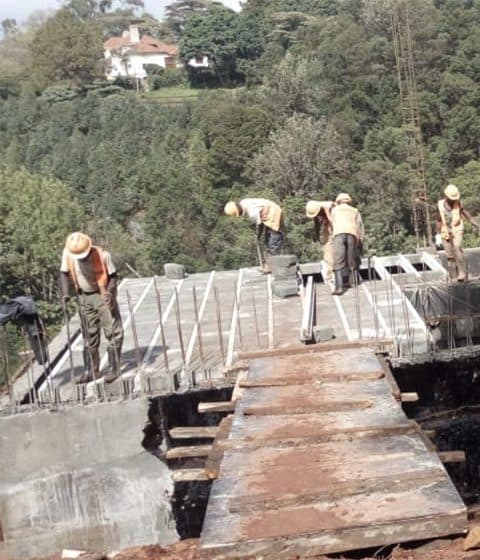

Why Beam and block slab is the ideal Solution

The client opted to use Beam and Block as this provided an ideal solution to several problems. As the site was so steep there was no place to set up a big batching area for the production of concrete. The only means to deliver concrete on the site was the wheelbarrow. This was already proving challenging for the concrete elements that needed to be cast on site. Beam and block were ideal as they could be carried directly to their final placement spot.

benefits of the beam and block flooring system

- As it was ready-made it left no debris on-site that would need to be cleared away later.

- It provided a safe working platform as soon as it was laid and helped with worker safety as a result.

- Being Tigoni the weather can be often wet. The beam and block is all-weather and can be laid even during the rain.

- Often sites such as this are in short supply of water. Beam and Block is beneficial as it does not require water.