The Beam and Block precast slab is a system that has been around since the 1970s. Relatively new in the Kenyan market but gradually becoming a popular alternative for builders in the country. Creating awareness of the beam and block precast slab is important because it educates the public about the floor system, how it works, and its advantages. Ecoconcrete organizes different events and sports tournaments entirely to facilitate the awareness tour campaign. The most recent event was a Golf Tournament held on the 7th of May in Thika sports club, Kiambu county.

ABOUT THE PRECAST TOUR

The golf tournament was organized by Ecoconcrete and other different sponsors like Sika Kenya and Muthokinju paints. Sika Kenya strives to provide value-added products in building finishes such as waterproofing, sealing, and bonding. The theme of the tournament was flat roofs using beam and block precast and Sika’s technology on waterproofing.

The event was a success, an intriguing tournament involving people from different parts of Kenya and professions. With an elaborate demonstration structure, the club members got a chance to see a complete beam and block slab. The installation process, and finishes as well as interacting with our engineers on a one-on-one basis. This allowed us to deconstruct misconceptions about the beam and block floor system.

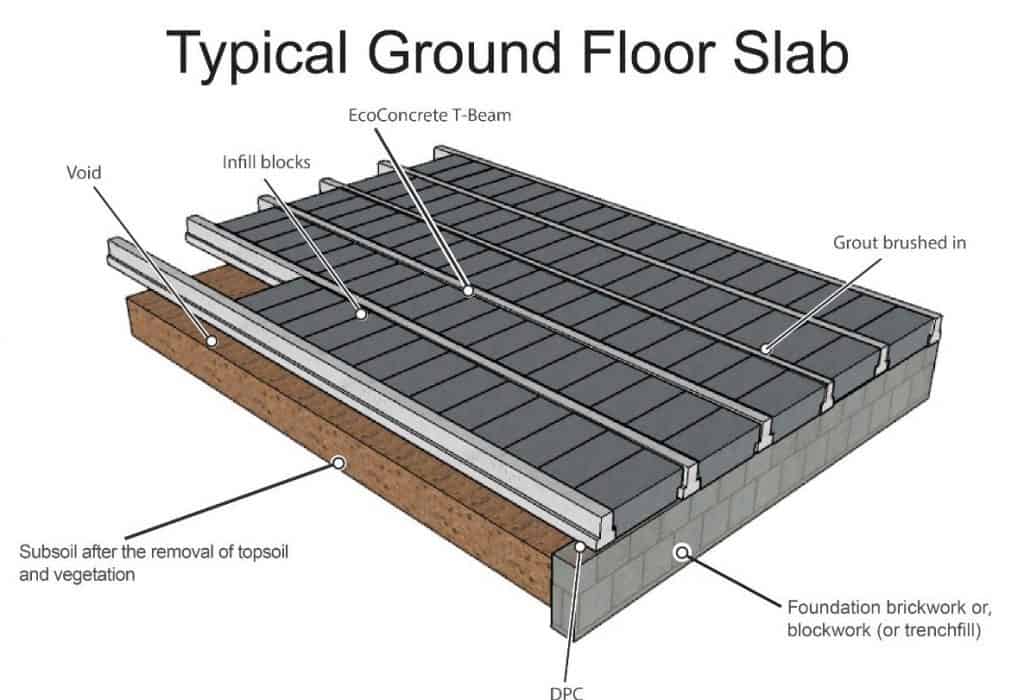

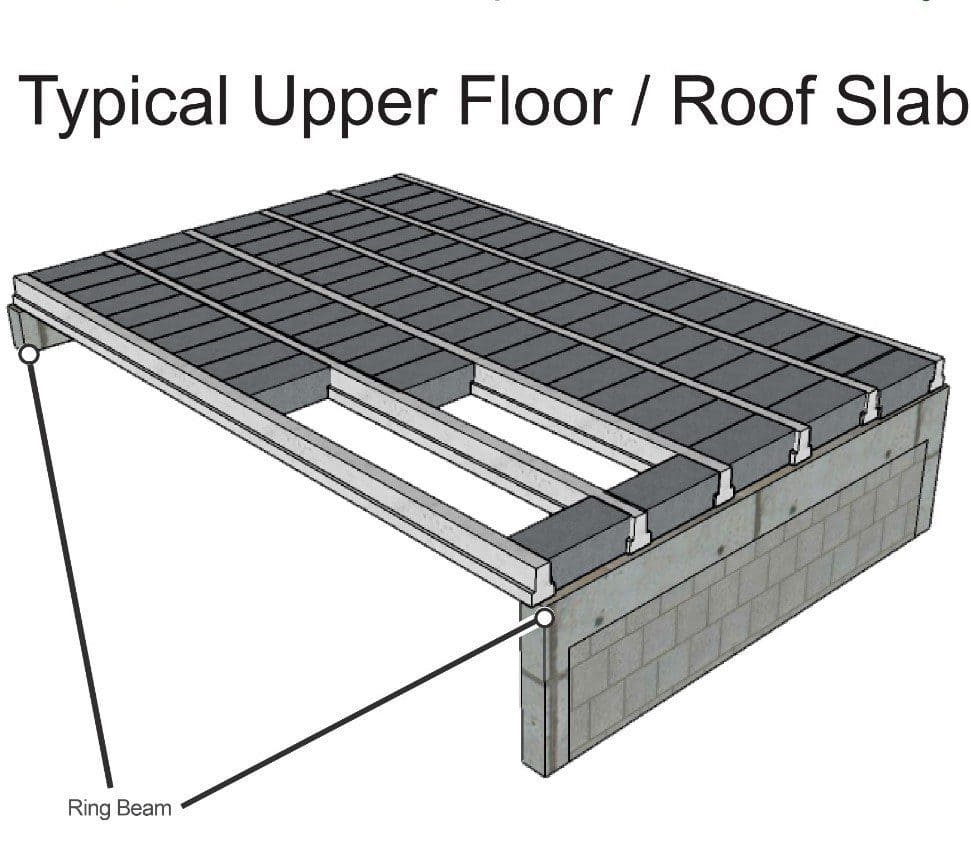

The slab system replaces traditional poured concrete floor slabs and is suitable for ground and upper-level floors. Made from pre-cast concrete the blocks and reinforced beams make up a complete slab that is very fast and easy to install. It provides an immediate working platform.

All the rules of construction apply, you require an Architect and a Structural Engineer for your build to follow all the building rules and regulations.

There are however a lot of benefits that come with the Ecoconcrete beam and block slab system.

- Quality assurance and Durability

Ecoconcrete beams and block slabs can withstand all weather elements. They go through extended periods of wear and tear and still maintain structural integrity.

- Fast to construct.

The beams and blocks are produced out of the construction site and delivered as a finished product ready for installation. After installation, there are no waiting periods for the slab provides a safe, ready working platform.

- Dump resistant.

The floor slab is suspended and rests on the ground beam. This restricts the movement of moisture through the walls and floors.

- Fire-resistant.

Precast concrete provides inherent fire protection and resiliency. Concrete does not combust and therefore helps contain fires in a controlled space. Sometimes referred to as computation (calculation of fire-resistant capabilities). It acts as a shield against radiation and fire penetration and protects occupants from the immediate effects of fire.

- Earthquake resistant.

The reinforcement in the precast concrete element takes up occurring tensile forces. The combination of the compression strength of the concrete and the tensile strength of the reinforcement results in optimum protection against high loads. Concrete can absorb extreme impacts, which means it can resist high-pressure forces.

- Soundproof

The precast concrete slab is manufactured with absorptive porous surfaces. Sound waves enter the absorptive air-like surface and not be reflected by the surface.

- Versatility

The beam and block slab can adapt to divergent functions which include.

- A floor/roof slab in a residential house and high-rise building.

- Warehouse roof slab.

- Water tank cover slab.

- Septic tank cover slab.

- No shuttering and formworks

The floor slab is suspended and does not require any support base during installation. The beams are placed from end to end on the ring beam. You do not have to cut down a whole forest for support hence our slogan is, Build environmentally.

CONCLUSION

The awareness campaign allowed us to widen the scope and create a bigger clientele base. Clients who fully understand the benefits of precast in these tough economic times, and how it contributes greatly to environmental conservation.

It really is that simple. The system is user-friendly and quick to install. A floor that could typically take 40 days will be done in 7! Saving you time and money. Contact us today for a free consultation on your project.

Call 0722882088 or,

WhatsApp 0113050865