What is EcoConcrete Beam & Block Slab?

What is a Beam & Block floor?

The beam and block floor system is fast becoming a popular form of domestic & commercial floor construction. It is an economical option due to off site manufacture of the beams and blocks, fast assembly and little requirement for specialist labour or equipment. The installation of a beam and block floor is not usually weather dependent and therefore specifying this form of construction can reduce site delays that other methods might encounter. Beam and block flooring demonstrates good noise reduction and fire resisting properties, and is also suitable to host underfloor heating systems.

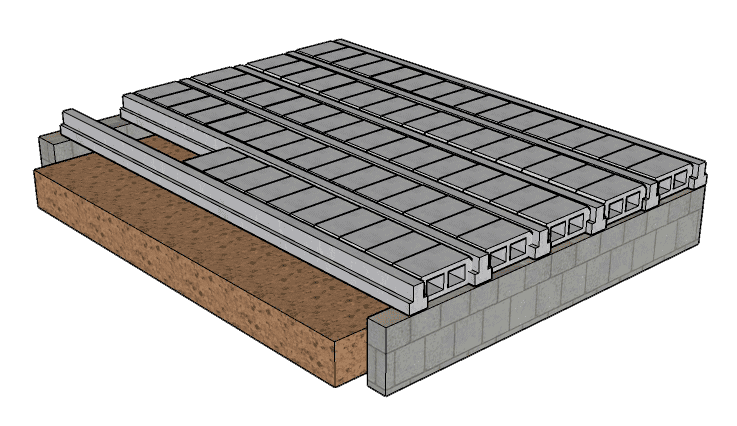

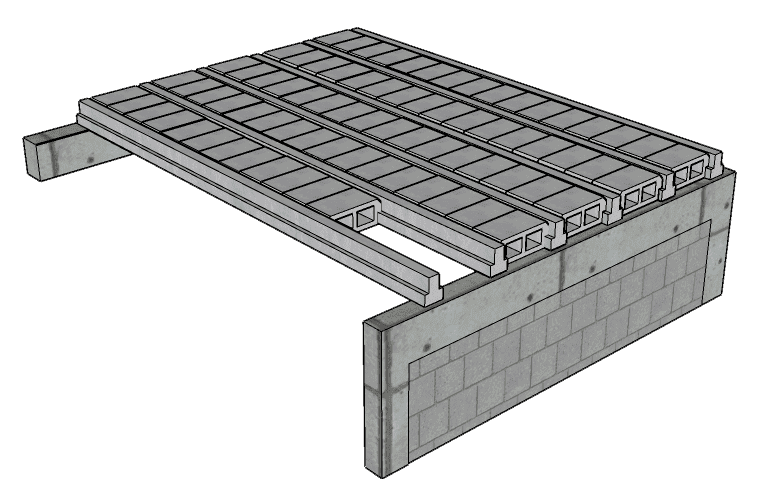

There are two types of concrete floor system commonly used in modern construction; ground bearing and suspended. Historically in Kenya we have used ground bearing, poured concrete slab. Beam & Block is a type of suspended concrete floor which is very common in more developed markets.

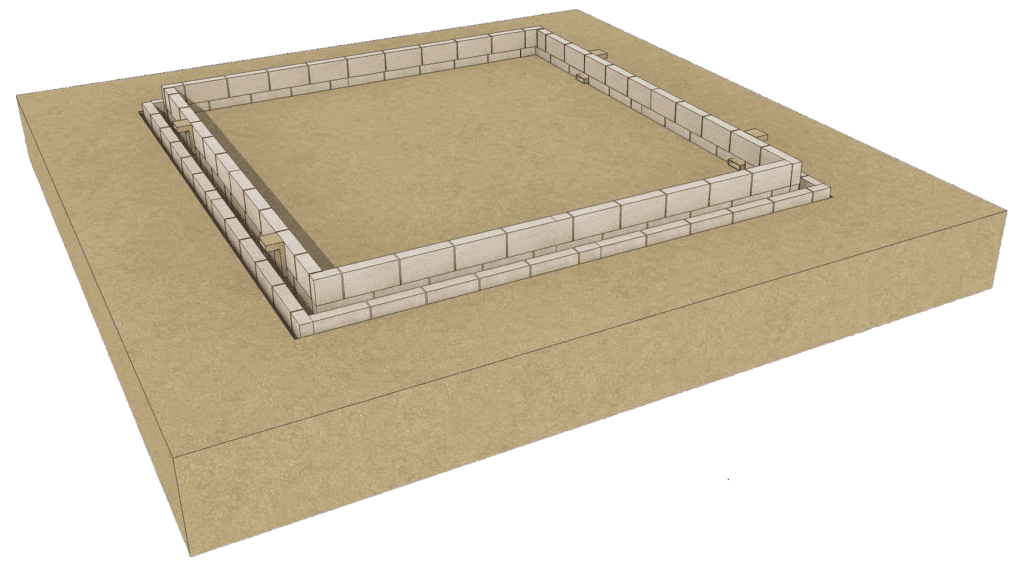

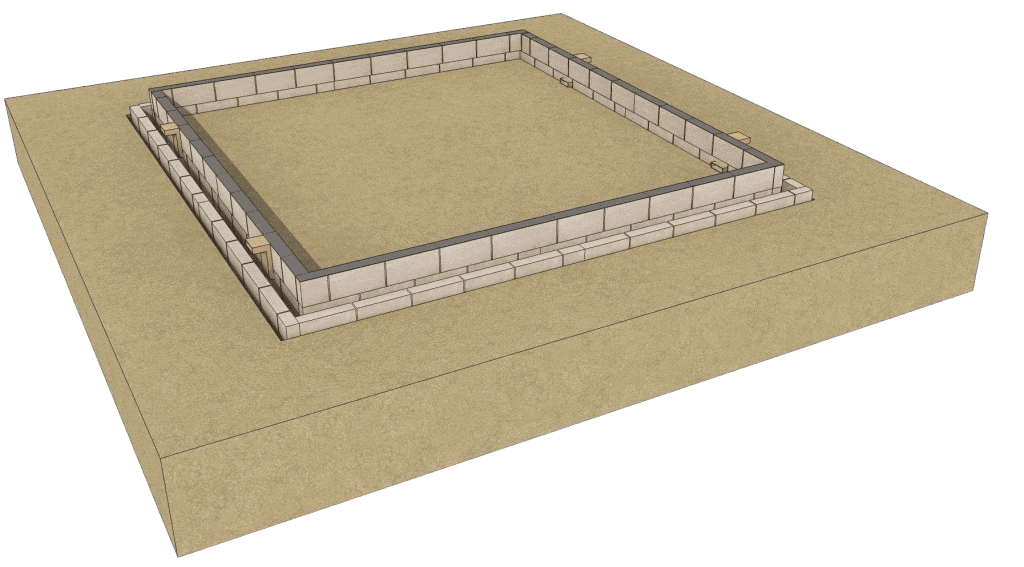

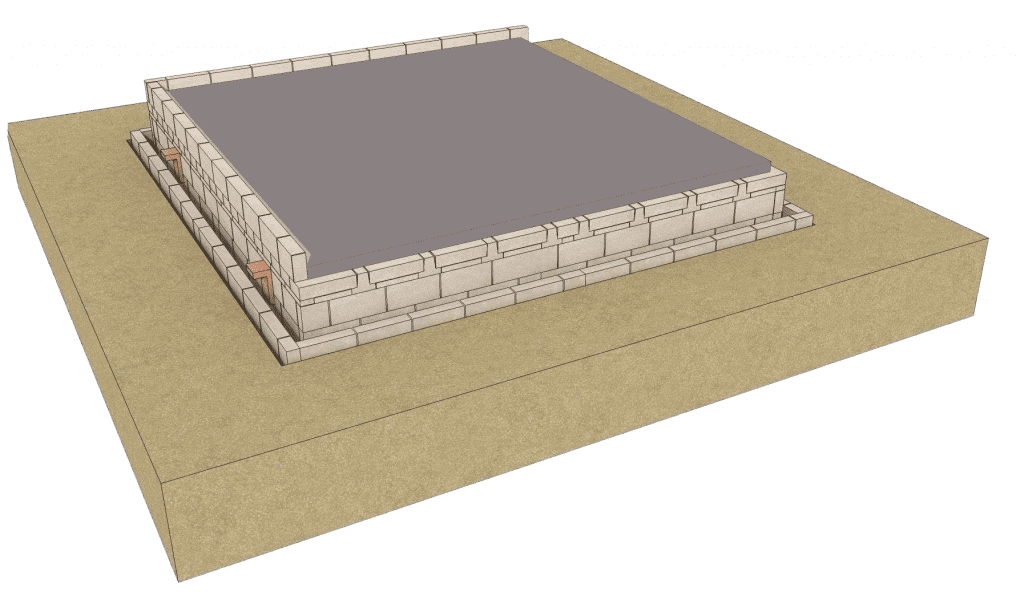

The suspended floor does not rely on support from the ground below but instead is supported by the external walls, and therefore the foundations below.

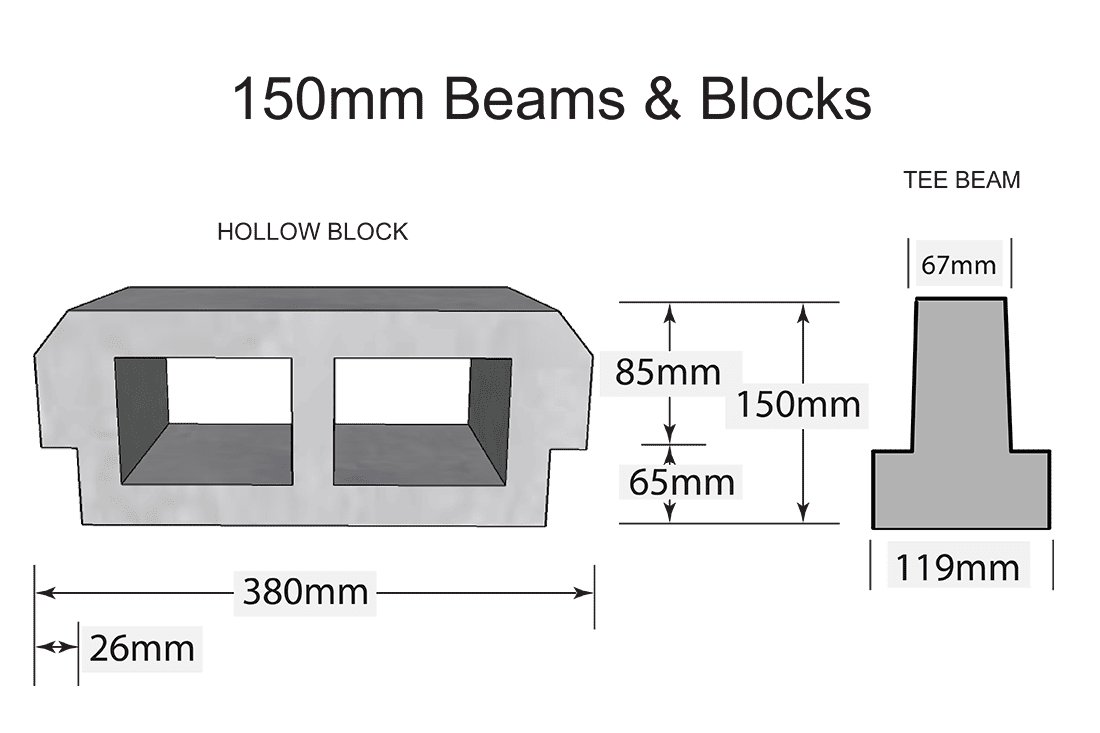

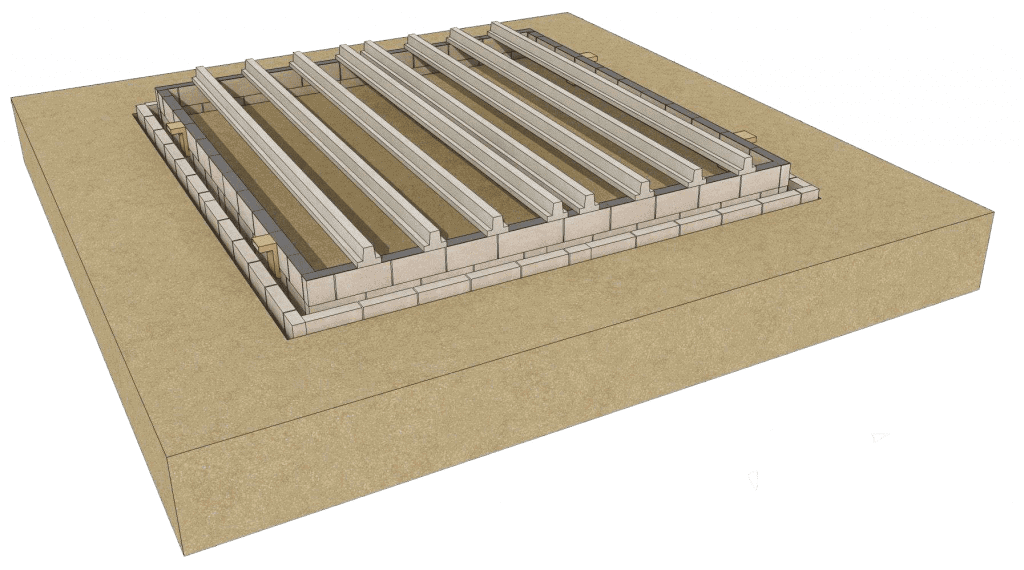

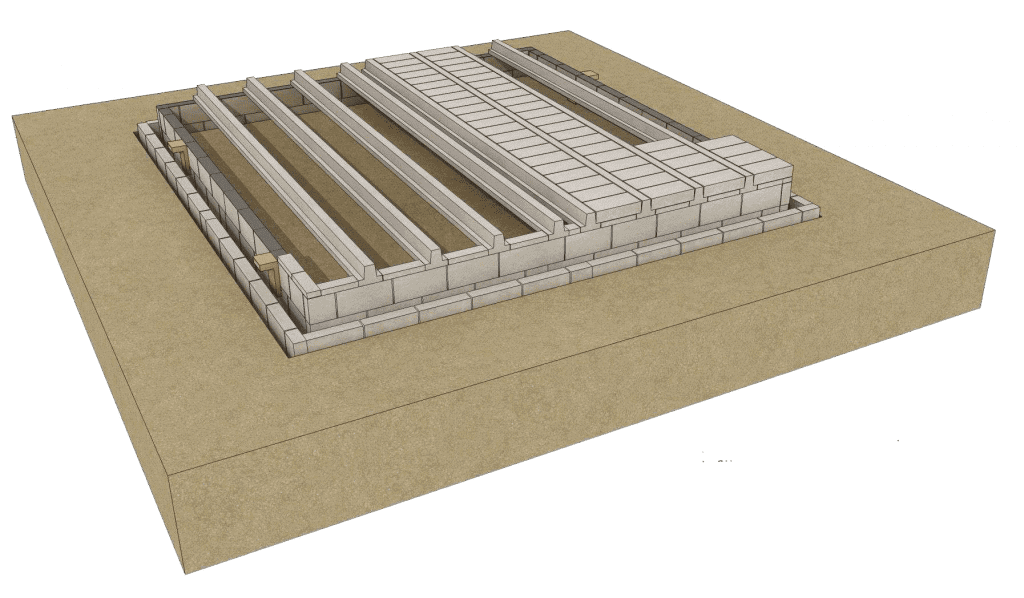

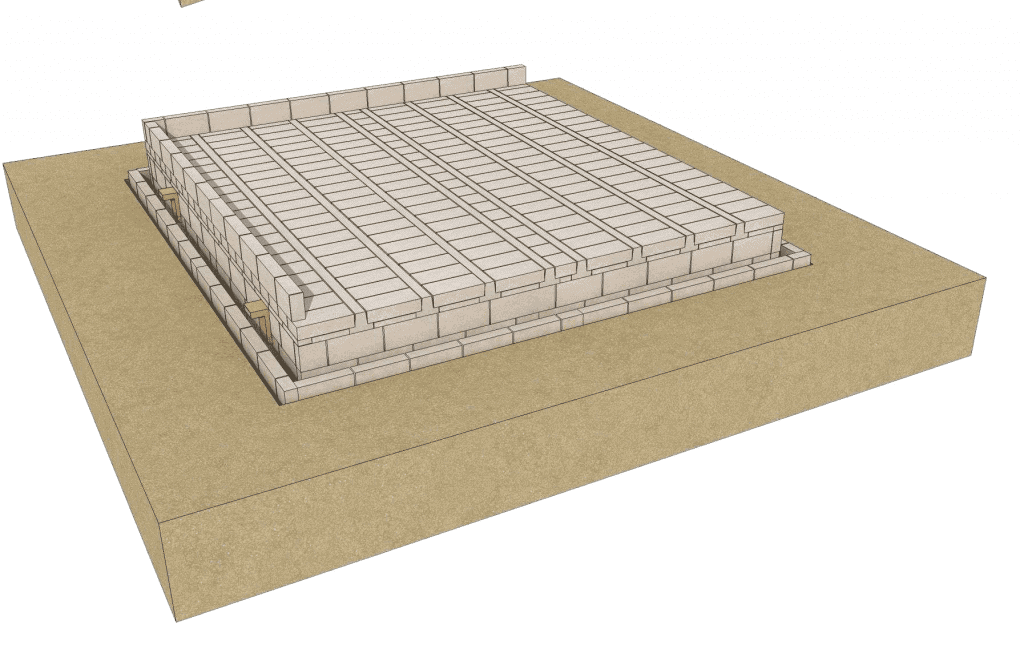

The precast concrete inverted T-beams are supported by the perimeter walls and internal load bearing walls. The beams vary in depth, and are 150mm or 225mm in depth, cast up to lengths up to 6m, they are designed and cast to fit your design. Beam depth and profiles are selected according to span and loading requirements, along with the type of block specified.

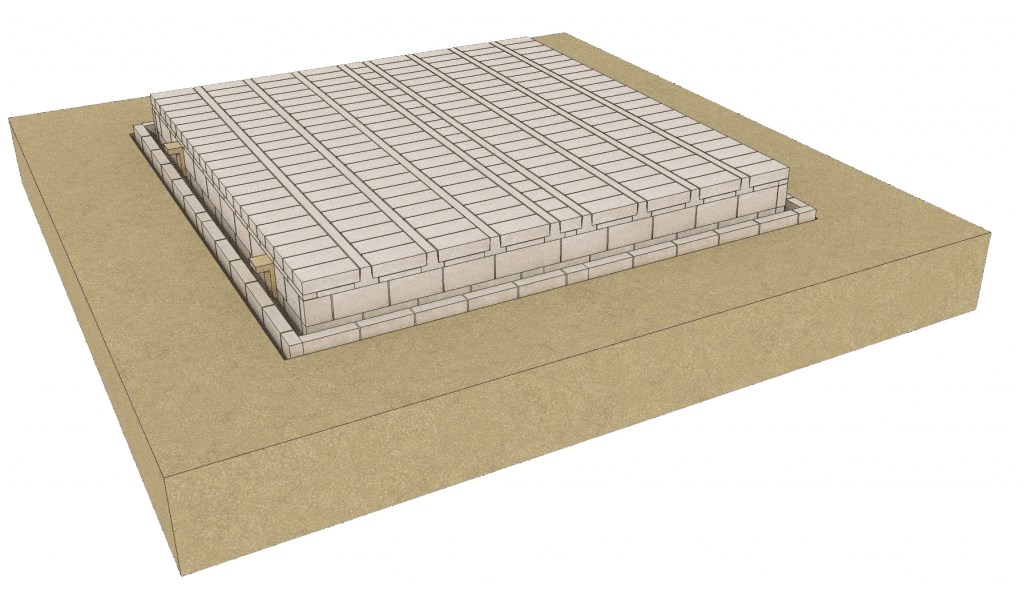

Infill blocks are then positioned between the T-beams, these blocks are usually lightweight concrete. A sand cement grout is brushed over the surface, filling any gaps providing a good load distribution and avoiding movement in the blocks. The grout also keeps insects and vermin out and assists with air tightness.

Our Working Process

1. Consultation

Firstly we will review your project and give you Free Value Engineering, making any recommendations you may need.

2. Quotation

Secondly once the Architect has done with your design, we will require either the drawings to enable us to give you a quote for the floor.

3. Measurements

When that’s agreeable then the process can begin. We will first confirm the measurements on site.

4. Delivery

As soon as you are ready on site for installation, we will deliver the Beam & Blocks for your floor or roof slabs.

5. Installation

One of our team of expert installers will come to your site to oversee the installation for free.

Advantages of Beam & Block

- Preliminaries: Beam and Block allows massive savings on preliminaries as there are savings on storage, security, space, time and labor.

- No Shuttering / Formwork Required: The Beam and Block system is a precast and designed product and does not require formwork for the soffit as does conventional slabs .This saves on costs.

- No Reinforcement Required: The Beams are made of Class 60 concrete, pre-stressed with high tensile steel, and manufactured to BS EN 15037, meaning there no need for additional reinforcement. This makes Beam and Block flooring economical.

- Reduction in Concrete Works: A 50mm to 75mm Fibre reinforced Screed or topping is required only.

- Fast and Easy Installation: The Beam and Block system is very quick and easy to install. Approximately 100 m2 of the system can be installed manually in a day. For conventional slab, it takes about 28 days for the slab to be completed from concreting, vibrating and curing. This can save about 90% of time. Minimal machinery is required on site. (No Concrete pump, No Poker Vibrator, No raking or levelling required).

- All Weather Construction: Installation can begin on delivery and is not influenced by weather conditions.

- Minimal Labour / Machinery required: A competent site supervisor and a few unskilled labour are required to install the system. This saves on costs. The beams can be carried and placed by hand, no lifting equipment required.

- Reduced Theft / loss of Materials from site: The Beam and Block system is uniquely designed for each build, it cannot be used on another site. It is stored in the open. The risk of theft / loss is minimal compared to steel and cement etc. as used in a conventional slab.

- Minimum Site Preparation for ground floor foundation: Only excavation of trenches for foundation walling or columns is required. No removal, cartage and fill and compaction of the ground floor slab as Beam and block is suspended. A minimum Void of 150mm (or 225mm in Black cotton) is required between underside of floor and ground surface. Saving costs and reducing site activity.

- Early working Platforms and quick progression of works: The floor itself becomes a working platform as soon as it is laid, allowing other works and walling to continue as soon as it is laid. Plumbing and electrical can be done upon completion of the structure saving time.

Featured Article

How to build with Beam & Block

- Construction Blog, by Gerald Taylor

Whether this is your first project or you are an experienced builder looking to try something new (and much quicker) Beam and Block can be the right solution for you. Here is a simple step by step guide to using the Ecoconcrete Beam & Block system. Read More…

- Step by Step Guide

- Timings Explained

- Clear Procedure

- Your Questions Answered

Learn More From

Frequently Asked Questions

It is a concrete product; we follow the same building guidelines and rules of a conventional slab. We have several advantages over conventional slab when it comes to price and ease of installation etc. Once the floor is completed there is no physical or observable difference between the two. |

The beams are made of high tensile steel which are stretched, and then concrete is poured over. After setting, the mechanical force applied during casting is released thereby stressing the wires in the concrete beam thus, the concrete is now effectively in a state of compression. It is capable of counteracting tensile stress, such as load.

The system reduces construction costs whilst maintaining the client’s expectations and quality of work. The system is faster, cost-effective, with minimum labour, no shuttering is required when compared to the traditional slab.

We use of high-tensile steel which is equivalent to D-16 wires as reinforcement.

The Beams cost around 1,100/= per length metre. However, we require your drawings to give you the full cost. The actual cost varies and will be based on your drawings and technical requirements. Depending on the location transport charges also vary.

Yes, If you include savings made on preliminaries, speed of build, no formwork, reduced labour, reduction of the total number of delivery vehicles, space-saving on site, low-security risk, all-weather installation, no overtime required, guaranteed quality, Just in time delivery, for low-level housing units no mechanical lifting required, minimal excavation. No mixing on site, No curing, No redundancy requirement for mixers and poker vibrators.

We are located on the 5th floor of Doctors Park, 3rd Parklands avenue, next to AGA Khan Hospital. |

Yes, we would like to know when you want to visit so that we can arrange with the production manager regarding the same.